Presentation on STUDY ON THE IDENTIFICATION OF INRUSH CURRENT OF POWER TRANSFORMER

Power transformers are one of the most important, expensive and essential elements in power system. Reliability and stability of the whole power system are the primary issues concerning transformers. Therefore, the continuity of transformer operation and their protection are of vital importance in maintaining the reliability of power supply. The major concern in power transformer protection is to avoid the false tripping of the protective relays due to misidentifying the magnetizing inrush current. Hence it is more than essential to identify the Inrush accurately to distinguish it from fault current and to convey this knowledge to the differential protective devices or means should be employed to mitigate it.

OBJECTIVES

- To study the source of Inrush Current in Power Transformer

- To study various characteristics of Inrush current on the basis of different design parameter of Power Transformer

- To study the problems in power system occurring due to inrush current of Power Transformer

- To make a comparative study of different techniques for identifying Inrush current

- To identify a better method of mitigation of Inrush current from different available techniques

- To simulate the transient inrush in Power Transformer.

WHAT IS INRUSH

Literally “Inrush” means “that rushes in”. An inrush current is the surge of transient current that rushes in a transformer when a transformer is energized. These currents are high magnitude, harmonic-rich currents generated when transformer cores are driven into saturation.

CAUSES OF INRUSH

Although usually considered as a result of energizing a transformer, the magnetizing inrush may be also caused by:

- Occurrence of an external fault,

- Voltage recovery after clearing an external fault.

TYPES

- Energization inrush

- Recovery inrush

- Sympathetic inrush

HOW IT OCCURS?

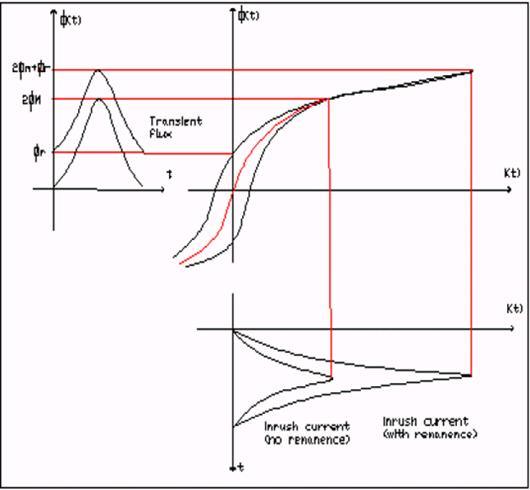

The driving force of the inrush current is the voltage applied to the primary of the transformer. This voltage forces the flux to build up to a maximum theoretical value of double the steady state flux plus remanence.

max=2m+r

Therefore, the transformer is greatly saturated and draws a large amount of current.

SHAPE, MAGNITUDE& DURATION OF INRUSHShape, Magnitude & Duration of Inrush Current depends on several factors:

- Size of a transformer

- Impedance of the system from which a transformer is energized

- Magnetic properties of the core material

- Remanence in the core

- Way a transformer is switched in

Power quality problems:

1.UNBALANCE 2.HARMONICS

Other disturbances caused by inrush:

- Incorrect operation and failures of electrical machines and relay systems

- Irregular voltage distribution along the transformer windings

- High amount of voltage drop at the power system at energization times

- Electrical and mechanical vibrations among the windings of the transformer

The schemes currently used to distinguish between magnetizing Inrush and fault current are based on:

- Second harmonics restraint principle,

- Voltage restraint principle,

- Restraint principle based on currents and voltages of the transformers

- But the second harmonic component is widely used for the detection of inrush current in power transformer.

- The magnitude of the second harmonic in fault current can be close to or greater than that present in the magnetizing inrush current.

- The second harmonic components in the magnetizing inrush currents tend to be relatively small in modern large power transformers

- Consequently, differential protection technique based on the second harmonic restraint may fail.

Some cheaper and easy to implement methods that do not rely on the presence of harmonic components to identify inrush are :

- Rectifier relay

- Waveform recognition or Dwell-time

- Power differential method

- Cross blocking

A number of mitigation techniques have been proposed through the years of investigation. External components such as resistors, thyristors, relays, timers and inrush thermistors in the primary circuit can be used to attenuate inrush. Here are some widely used inrush mitigation techniques:

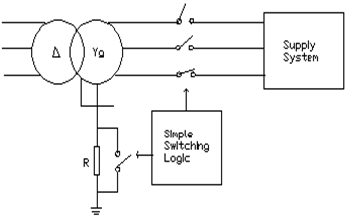

INRUSH MITIGATION USING PRE-INSERTION RESISTOR

A resistor inserted in series with primary winding will reduce the inrush current during switch on.

INRUSH MITIGATION USING NTC THERMISTOR

TRANSFORMER INRUSH CURRENT REDUCTION BY FLUX REDUCTION METHOD

A new simple and efficient technique for inrush current reduction is based on core flux reduction prior to primary circuit energization. Flux reduction can be achieved by applying a voltage to the core with the help of a tertiary winding. However, incorporating a tertiary winding of rating same as primary is a costly affair for a large power transformer. Hence, reducing the rating of the tertiary winding is tested; it is observed that appreciable inrush reduction could be achieved.

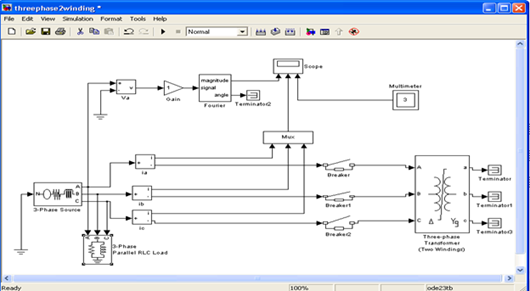

MATLAB SIMULATION

SYMPATHTIC INRUSH

SIMULATION OF ENERGIZATION INRUSHTHREE PHASE SIMULINK MODEL

Phase-phase current waveform

Flux, current and breaker voltage waveform

Flux, current and breaker voltage waveform (in Scope)

SINGLE PHASE SIMULINK MODEL MODEL FOR ENERGIZATION INRUSH & REDUCTION USING PRE-INSERTION RESISTOR

INRUSH WAVEFORM

REDUCED INRUSH

CONCLUSION

Some methods for identifying inrush current are discussed and some well known cheap and widely used mitigation techniques have been studied with their merits and demerits. But still there is no boundary of improvement in this field. It may be stated emphasisly that inrush current is a sector to give attention to find still better way of identification and mitigation.

Submitted by Muhammad Imrul Ahsan and Joydeep Chowdhury

A winding machine has contained with metal wire, string or paper, onto an inside, spool, or bobbin, which are particular sorts of bowing machines from clear manual keep up machines to complex PC numeric control (CNC) machines. Considering all things, the titanic bit of the winding machines has turn winding, rope winding, and holding tight fiber winding.automatic winding machine

ReplyDeleteThe real highlights of ferrite material are motion thickness is isolated by drive level, the power materials is ordinarily utilized for high recurrence application standard so it having high transition thickness and low misfortunes. The transition thickness is may fluctuated in view of its motion go.automatic winding machine

ReplyDeleteThe XFLUX is connected for little and direct scope of inductors and gags. The immersion level is high in the valuable application though inductance has substantial stacked in UPS and power factor revision support.automatic winding machine

ReplyDeleteThe Winding Machines are amalgamate with the most recent CNC control with alpha-numeric screen that has two or four lines openly, which show principal information for the working staff. For instance, the standards are utilizing like as number of working advances, number of turns, feeling of sensation, and errand of things.automatic winding machine

ReplyDeleteOther than the obviously made course out of movement, the CNC unit offers a disaster area secured comfort with pictures that demand phenomenally real programming.

ReplyDeleteThe CNC control can guarantee working condition that accomplices with a mind-boggling setting up of winding endeavors.automatic winding machine

The CNC control can make certain workplace that empowers a rich setting up of winding undertakings. This suggests wire isolate over, various turns, speed, winding width and all critical winding parameters are secured under one working progression number. Beyond what many would consider possible are not required to deal with this factor, which each winding parameter are showing up by press the photograph keys.automatic winding machine

ReplyDelete