DISCUSSION

Description of the module

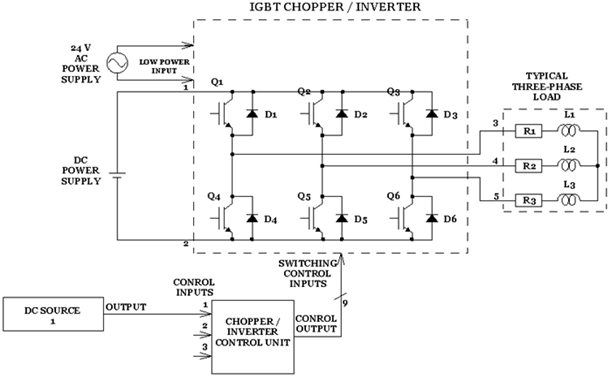

The IGBT Chopper / Inverter module mainly consists of 7 insulated-gate bipolar transistors (IGBT). An IGBT is a switching transistor that requires voltage on the gate to conduct. The IGBTs of the IGBT Chopper/Inverter module are labeled Q1 to Q7. IGBTs Q1 to Q6 are grouped in pairs as follows: Q1 with Q4, Q2 with Q5 and Q3 with Q6 and Q7 is part of the breaking circuit which limits the voltage on the DC bus. The module also contains electronic circuitry that isolates the gate of IGBTs and protects the IGBTs against overheating, overvoltage and over current.

F7-6 shows the front panel of the IGBT Chopper / Inverter Module. It shows many important characteristics about the operation of the module.

The DC voltage is applied through terminals 1 and 2 to supply the DC bus.

The DC bus is linked to IGBT Q1 and Q4 to supply loads from terminal 3. The DC bus may also be linked to IGBTs Q2 and Q5 through switch S1 and to IGBTs Q3 and Q6 through switch S2 to supply three- phase loads from terminals 3, 4 and 5.

Capacitor C1 is used to maintain a smooth DC voltage in spite of the current pulsations produced by the IGBTs. It is connected between terminals 1 and 2.

A power diode is connected between the collector and emitter of each IGBT. The diodes connected in parallel with the IGBTs have a very short recovery time. This important feature allows the IGBT Chopper / Inverter module to be used in high speed power switching circuits.

F7-6: Front panel of the IGBT Chopper / Inverter module.

Protection circuits

The IGBT Chopper / Inverter module contains many electronic circuits that protect the IGBTs against various types of overloads. The operation of each protection circuit is briefly described in the following paragraphs.

The positive and negative branches of the DC bus are individually protected by breakers. When an overload condition occurs on the DC bus, one of the breakers trips. Correct the faulty condition and corresponding pushbutton to reset the breaker.

Over current protection circuit

The over current protection circuit is designed to protect IGBTs Q1 to Q6 against instantaneous over current. When an over current condition is detected on either IGBT, the six IGBTs are switched off by setting the gate voltage at 0 V. when this condition occurs, the OVERCURRENT LED turns on. The OVERCURRENT RESET pushbutton must be depressed to reset this protection circuit.

Overvoltage protection circuit

The overvoltage protection circuit is designed to protect IGBTs Q1 to Q6. This protection circuit senses the DC bus voltage. When the voltage exceeds a safe value, the six IGBTs are switched off by setting the gate voltage at 0 V and the OVERVOLTAGE LED turns on t indicate the faulty condition. The overvoltage protection circuit is automatically deactivated when the DC bus voltage returns to a safe value.

Overheat protection circuit

IGBTs Q1 to Q6 are also protected against overheating. The overheat protection circuit senses the heat sink temperature of the IGBTs. When the temperature exceeds a safe value, the six IGBTs are switched off by setting the gate voltage at 0 V and the OVERHEAT LED turns on to indicate the faulty condition. The overheating protection circuit is automatically deactivated when the temperature returns to safe value.

Breaking circuit

The breaking circuit consists mainly of the diode D7, resistor R1 and IGBT Q7 shown on the module panel. This circuit is designed to dissipate the energy produced by a decelerating motor connected to the IGBT Chopper / Inverter module. When the motor decelerates, it behaves like a generator and some power is returned to the DC bus. When the DC bus voltage exceeds a safe level, the braking circuit transfers some energy from the DC bus to resistor R1 and the BRAKING LED flashes. Notice that the module continues to operate in this condition. The braking circuit may be disabled by setting the BRAKING switch at 0.

Interconnection with control module

The gate of IGBTs Q1 to Q6 is connected to the SWITCHING CONTROL INPUTS connector through a series of internal isolators and amplifiers. This 9-pin connector may be connected to the CONTROL OUTPUTS of the Chopper/Inverter Control Unit module, or to the FIRING CONTROL OUTPUTS of the Thyristro Firing Unit.

The pin configuration of the SWITCHING CONTROL INPUTS connector is given in F7-6. The inputs (pins 1 to 6) require 0-5 V transition of the control signals. Pin 7 is used to input a synchronization signal coming from the Chopper/Inverter Control Unit or the Thyristor Firing Unit.

The miniature banana jacks identified SWITCHING CONTROL INPUTS 1 to 6 are parallel connected to pins 1 to 6 of the SWITCHING CONTROL INPUTS 9-pin connector, respectively. This allows switching control signals coming from other equipment to be used to control the IGBTs.

The SYNC. OUTPUT miniature banana jack provides the synchronization signal coming from the Chopper/Inverter Control Unit or from the Thyristor Firing Unit. This 0-5 V signal may be used to synchronize an oscilloscope when observing the switching control signals.

The SWITCHING CONTROL INPUTS DISABLE miniature banana jack allows to switch off IGBTs Q1 to Q6 by applying a +5-V voltage to this jack. In this condition, the IGBT gate voltage is 0 V, and the IGBTs cannot be controlled. They can be controlled when the SWITCHING CONTROL INPUTS DISABLE miniature banana jack is simply left open or connected to the common.

A 24-V AC power supply must be connected to either one of the two LOW POWER INPUT jacks to supply the electronic circuits. The POWER ON LED lights when AC voltage is applied.

The chassis terminal (green) on the front panel of the IGBT Chopper / Inverter module is used to prevent harmful electromagnetic emissions from interfering with other components. To do so, the shield of a special connection cable must be connected to this terminal.

Using the IGBT Chopper / Inverter module

The IGBT Chopper / Inverter module is used to build various power electronic circuits such as choppers and inverters. F7-7 and 7-8 show examples of such power electronics circuits.

In the circuit of F7-7, IGBT Q1 and power diode D4 are used to build a bulk chopper. IGBT Q4 (parallel connected to power diode D4) and power diode D1 (parallel connected to IGBT Q1) are not shown in the figure because they are not used in this circuit.

In this circuit, SWITCHING CONTROL INPUT 4 of the IGBT Chopper / Inverter module is connected to common point to prevent IGBT Q4 from being switched on.

F7-7: Buck chopper built using the IGBT Chopper / Inverter module.

In the circuit of F7-8, the six IGBT Chopper / Inverter module form a three-phase inverter.

In the circuit of F7-7 and 7-8, the Chopper/Inverter Control Unit provides the control signals required to switch the IGBTs on or off.

Notice that in both circuits, a 24-V AC power supply is connected to the LOW POWER INPUT of the IGBT Chopper / Inverter module to supply the internal circuits. Also, notice that the capacitor connected on the DC bus has been intentionally omitted to simplify the diagrams.

The IGBT Chopper / Inverter module can be used with the Thyristor Firing Unit to build the Three-phase inverter shown in F7-8.

F7-8: Three-phase inverter built using the IGBT Chopper / Inverter module.

have never thought that surfing online can be so much beneficial and having found your blog I feel really happy and grateful for providing me with such priceless information. oklahoma city roofing

ReplyDeleteHow to find brake resistor value?

ReplyDelete