Setting up the equipment

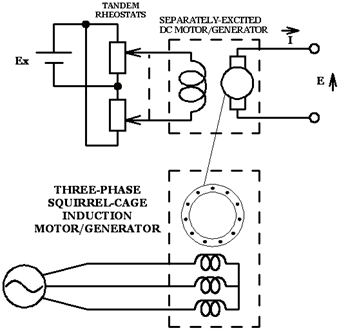

(1) Install the Power Supply, the Enclosure / Power Supply, the DC Motor Generator, the Four-pole Squirrel-Cage induction Motor, the Smoothing inductors, the DC Voltmeter/Ammeter, the Three-Phase Wattmeter/Varmeter, the Tandem Rheostats and the Power-Thyristors modules in the Mobile Workstation.

Note: Align the brushes of the DC Motor / Generator in the neutral position by centring the metal tab on the red mark (on the casing).

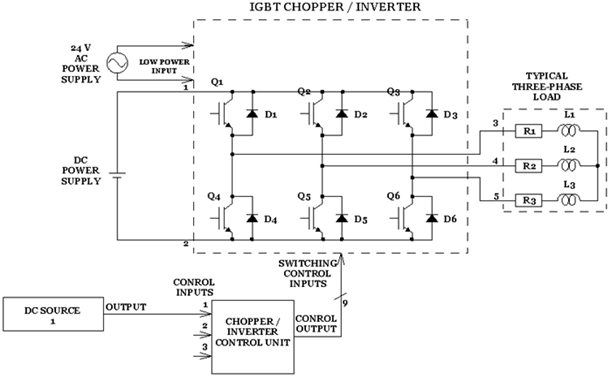

(2) Install the Thyristor Firing Unit and the Current/Voltage isolators in the Enclosure / Power Supply.

Note: Before installing the Thyristor Firing Unit, make sure that switches SW1 and SW2 (located on the printed circuit board) are in the 0 position.

(3) Make sure that the main power switch of the Power Supply is set to the 0 (OFF) position. Connect the Power Supply to a three-phase wall receptacle.

(4) Plug the Enclosure / Power Supply line cord into a wall receptacle. Set the rocker switch of the Enclosure / Power Supply to the 1 (ON) position.

(5) On the Power Supply, set the 24-V ac power switch to 1 (ON) position.

Rectifier and inverter modes

In the exercise, you observed that a three-phase, six-pulse converter can operate both as a rectifier and as an inverter. You demonstrated that the static transfer function obtained experimentally is similar to the theoretical curve.

REVIEW QUESTIONS

(1) Install the Power Supply, the Enclosure / Power Supply, the DC Motor Generator, the Four-pole Squirrel-Cage induction Motor, the Smoothing inductors, the DC Voltmeter/Ammeter, the Three-Phase Wattmeter/Varmeter, the Tandem Rheostats and the Power-Thyristors modules in the Mobile Workstation.

Note: Align the brushes of the DC Motor / Generator in the neutral position by centring the metal tab on the red mark (on the casing).

(2) Install the Thyristor Firing Unit and the Current/Voltage isolators in the Enclosure / Power Supply.

Note: Before installing the Thyristor Firing Unit, make sure that switches SW1 and SW2 (located on the printed circuit board) are in the 0 position.

(3) Make sure that the main power switch of the Power Supply is set to the 0 (OFF) position. Connect the Power Supply to a three-phase wall receptacle.

(4) Plug the Enclosure / Power Supply line cord into a wall receptacle. Set the rocker switch of the Enclosure / Power Supply to the 1 (ON) position.

(5) On the Power Supply, set the 24-V ac power switch to 1 (ON) position.

Rectifier and inverter modes

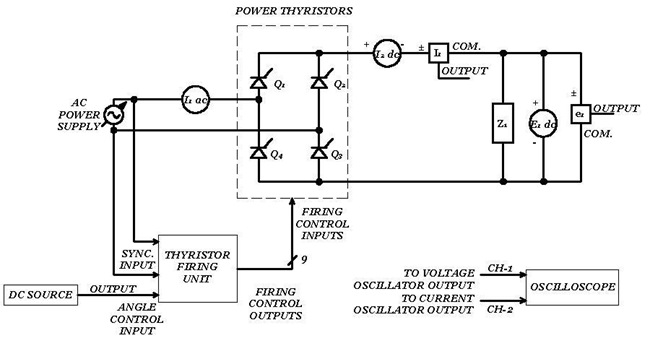

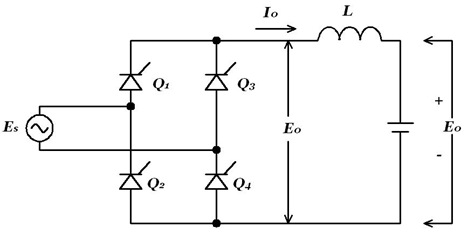

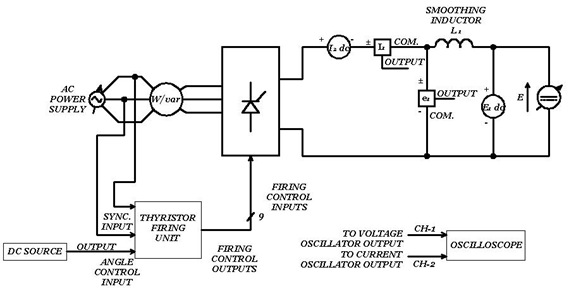

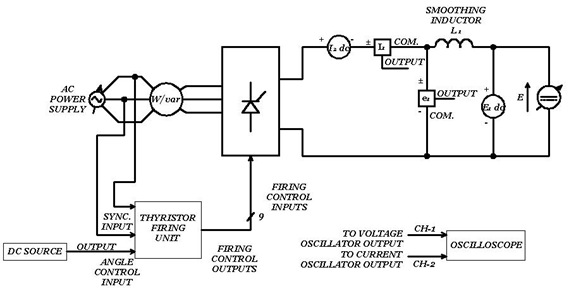

(6) Set up the circuit of Figure 4.

Figure 4: Three-phase, six-pulse converter circuit.

LINE

VOLTAGE

(Vac)

|

I1 dc

(A)

|

I1

(A)

|

e1

(V)

|

E1 dc

(V)

|

L1

(H)

|

| 120 | 2.5 | 10 | 300 | 150 | 0.2 (3 A dc max.) |

| 220 | 1.5 | 5 | 600 | 300 | 0.8 (1.5 A dc max.) |

| 240 | 1.5 | 5 | 600 | 300 | 0.8 (1.5 A dc max.) |

(7) Make the following settings:

On the Power Supply

Voltage Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

On the Thyristor Firing Unit

ANGLE CONTROL COMPLEMENT . . . . . . . . . . . . . . . . . 0ANGLE CONTROL ARC COSINE . . . . . . . . . . . . . . . . . . . 0FIRING CONTROL MODE . . . . . . . . . . . . . . . . . . . . . . 3~DC SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MAX.

On the Oscilloscope

Channel-1 Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . 5 V/DIV. (DC coupled)Channel-2 Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . 1 V/DIV. (DC coupled)Time Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 ms/DIV.Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LINE

(8) On the Tandem Rheostats, set the control knob to the centre position. On the power Supply, make sure that the voltage control knob is set to the 0 position, then set the main power switch to 1 (ON). The Four-Pole Squirrel-Cage Induction Motor should begin to rotate.

On the Power Supply, adjust the voltage control knob to obtain the line-to-line voltage shown in table 1, as indicated by the voltmeter on the Power Supply. | LINE VOLTAGE | LINE-TO-LINE VOLTAGE |

Vac

|

Vac

|

| 120 | 90 |

| 220 | 175 |

| 240 | 175 |

Table 1: Line-to-line voltage.

Turn the control knob on the Tandem Rheostats to adjust the voltage E of the dc source to the level indicated in Table 2.

LINE

VOLTAGE |

DC SOURCE

VOLTAGE

E1dc

|

Vac

|

V

|

120

|

100

|

220

|

200

|

240

|

200

|

Table 2: DC source voltage E1.

Vary the firing angle and observe the effect on the waveforms and on the current delivered to the active load. How does the current vary as the firing angle is reduced to 0°? . . . . . . . . . . . . . . . . . . . . . . . . .

(9) On the Thyristor Firing Unit, adjust the FIRING ANGLE to 0°, adjust the Tandem Rheostats to obtain the current I1 shown in Table 3.

LINE

VOLTAGE |

CURRENT

I1dc

|

Vac

|

A

|

120

|

0.5

|

220

|

0.25

|

240

|

0.25

|

Table 3: Current I1 delivered to load.

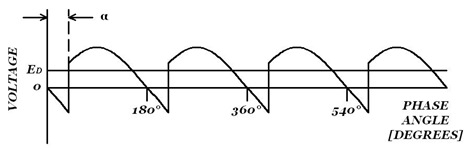

For each FIRING ANGLE in Table 4 adjust the Thyristor Firing Unit to the given firing angle, then adjust the Tandem Rheostats to obtain the current I1 Shown in Table 3. Observe the waveforms on the oscilloscope. Calculate the theoretical output voltage, record the measured voltage E1dc as well as reactive power, and calculate the active power delivered to the reversible dc power supply.

Note: Do not increase the firing angle beyond 165° or the current will increase suddenly. If this happens reduce the firing angle to approximately 120° to restore normal operation.

FIRING

ANGLE |

THEORETICAL VOLTAGE

E0 = 1.35 Es cos

|

MEASURED

VOLTAGE E1dc |

ACTIVE

POWER

P = E1 × I1

|

REACTIVE

POWER

Q

|

degree

|

V

|

V

|

W

|

var

|

0

| ||||

15

| ||||

30

| ||||

45

| ||||

60

| ||||

75

| ||||

90

| ||||

105

| ||||

120

| ||||

135

| ||||

150

| ||||

165

|

Table 4: Data for three-phase, six-pulse converter.

(10) Turn the knob on the Tandem Rheostats to the centre position, so the field current in the DC Motor / Generator is zero. On the Power Supply, set the voltage control knob to 0 then set the main power switch and the 24-V ac power switch to 0 (OFF).

For what range of firing angle does the converter operate as a rectifier? For what range does it operate as a inverter? Explain. . . . . . . . . . . . . . . . . . . . . .

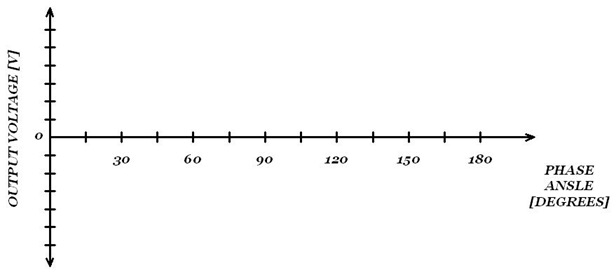

In Figure 5, plot the output voltage E1 versus the firing angle. Then, in the same figure, plot the theoretical relationship E0 = 1.35 Es cos , where Es is the line voltage. Compare the two curves.

Figure: 5

Describe how the active and reactive power change as the firing angle is varied. . . . . . . . . . . . . . . .

(11) Set the rocker switch on the Enclosure / Power Supply to the 0 position. Remove all leads and cables.

CONCLUSIONIn the exercise, you observed that a three-phase, six-pulse converter can operate both as a rectifier and as an inverter. You demonstrated that the static transfer function obtained experimentally is similar to the theoretical curve.

REVIEW QUESTIONS

- What are the advantages of the three-phase, six pulse converter over other rectifier/inverter circuits? . . . . . . . . . . . . . . . . . . .

- Why is it advantageous to have a high ripple frequency at the output of a rectifier? . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- What is the average output voltage E0 for a three-phase, six pulse converter if the line-to-line source voltage is 240 V and the firing angle is 75°? . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- What is the average current in each of the three ac line in a three-phase, six-pulse converter? . . . . . . . . . . . . . . . . . . . . .

- What are the advantages and disadvantages of a three-phase bridge made with three thyristors and three diodes? . . . . . . . . .