previous FLUMES

To maintain accuracy obtained by a primary device, a flowmeter must measure fluid level at the measuring point and precisely convert it to flow rate. This entails choosing a level measuring device appropriate for site conditions.

1. Operating Principles: Level measuring devices operate using either the time for sonic echo response from surface to bottom of liquid flow or differences in atmospheric pressure between surface and bottom of liquid flow. The application of these principles is described in various meter designs.

METER DESIGNS: Each of the meter types discussed are available with the capability to integrate flow level data with preprogrammed data specific to the site and provide an accurate flow rate.

1. Ultrasonic Level Meters: This type of level meter incorporates timing of ultrasonic pulses and echoes to determine liquid level. A sensor/transducer is fixed above the surface and is unaffected by the type of liquid (Figure 7-6) . The transducer emits a signal directed at the surface of the liquid and measures the time interval of echo response.

2. Bubble Type Meter: The sensing probe for this type of meter is mounted below the surface of the liquid (usually at the bottom) (Figure 7-7). The probe contains a pressure sensitive transducer and a tube for releasing gas for bubble formation. The sensor measures pressure required to produce bubbles. The relationship that exists between bubble pressure and head provide data to determine flow rate.

FIGURE 7-6. Ultrasonic Level Meter

FIGURE 7-7. Bubble Level Meter

3. Submerged Probe: The submerged probe type level meter is a differential pressure transducer that relates pressure created by the liquid head to atmospheric pressure (Figure 7-8).

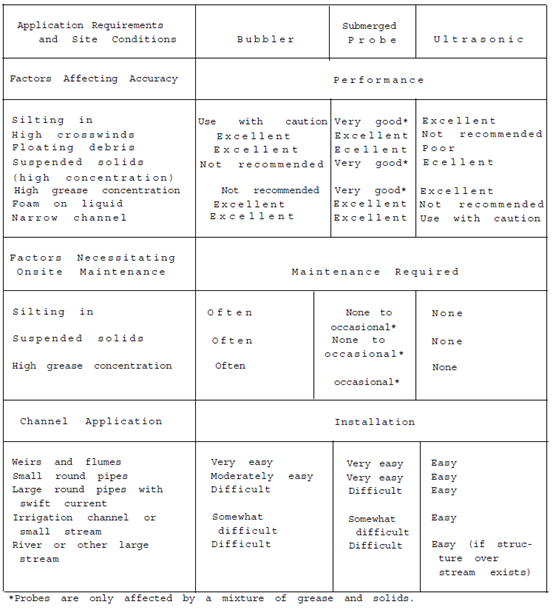

4. Meter Selection: Table 7-1 illustrates typical site conditions and possible meter applications and requirements.

LIMITATIONS: Level measuring devices have the following limitations:

- Must have access such as manhole or handhole for installation.

- Must have electrical power source.

- Must have compressed air source.

- Does not have provisions for digital data transmission and recording.

FIGURE 7-8. Submerged Probe Level Meter

TABLE 7-1. Level Meter Selection Guide

MAINTENANCE: Level measuring devices require inspection and calibration every six months. For mechanical devices, ensure that all moving parts work freely and correctly. For electronic devices, check sensors and processing equipment for calibration. All devices require periodic viewing to ensure that material has not accumulated on or damaged the device resulting in erroneous or no data.

ACCURACY AND RELIABILITY: Level-sensing devices differ in the method of operation, but accuracies of ±1.0% and repeatabilities of ±0.1% can be expected. Since level-sensing devices are accurate to ±1.0%, the developed relationship between flow level and channel becomes the area of least accuracy in the system. Combining the two devices produces a probable accuracy range of ±1.0 to ±8.0%. Reliability of these systems is very good, if basic maintenance is performed.

0 comments:

Post a Comment

Please wait for approval of your comment .......