Presentation on SPEED CONTROL OF A DC MOTOR BY USING PWM TECHNIQUE

OBJECTIVE:

- Design and construction of speed control system of a dc motor.

- To use voltage control method to control the speed of the dc motor.

- Implementation of our project by an electronic circuit.

- To use 8-bit data from computer through parallel cable to the DAC, then to op-amp, PWM generator and to the MOSFET and to the motor, to control the speed of the dc motor.

IMPORTANCE:

There are various types of motor drive working all over the world. These motors are used to drive the various types of loads. With respect to the loads these motors requires various types of speed. So, there is a great need of many speed controlling devices.

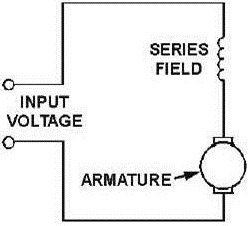

DC series motor:

The series motor provides high starting torque and is able to move very large shaft loads when it is first energized.

MOTOR CHARACTERISTICS:

- Torque.

- Power.

- Speed.

- Torque vs Speed Curves.

- Power Curves.

Parallel port:

A parallel port is a type of interface found on computers (personal and otherwise) for connecting various peripherals. It is also known as a printer port . The Parallel Port is the most commonly used port for interfacing home made projects. This port will allow the input of up to 9 bits or the output of 12 bits at any one given time, thus requiring minimal external circuitry to implement many simpler tasks. The port is composed of 4 control lines, 5 status lines and 8 data lines. It's found commonly on the back of your PC as a D-Type 25 Pin female connector. There may also be a D-Type 25 pin male connector. This will be a serial RS-232 port and thus, is a totally incompatible port.

Parallel port:

Interfacing:

Computer interfacing: the art of connecting computers and peripherals. In a lot of circumstances, it looks more like magic than art. It is not uncommon that you end up removing all unnecessary hardware from your computer to get that communication device to work. Despite all plug-and-play internal hardware solutions for the PC, connecting a number of external devices still requires some amount of technical knowledge and experience.

PWM Technique:

- In controlling direct current motors, it is possible to use resistor, autotransformer, transistor etc. to carry out linear current control. The above items are used for dc motor control have very large power consumptions.

- At present there are two kinds of controlling devices most often used.

- Pulse width modulation PWM uses a fixed frequency to do opening and closing action , and adds dc power to the motor to control the on/off time of the switch and also control the average voltage. This is called duty cycle control method.

- Pulse frequency modulation (PFM) ensures the on/off time of the power source and motors are same and that the on/off frequency influences the average amount of voltage to change the motor’s speed.

BLOCK DIAGRAM:

Circuit Diagram:

Limitation:

The main limitation involved with our motor controller is the Electromagnetic interference (EMI). We know the switching or commutation of any switch generates voltage and current transients that are characterized by a whole spectrum of frequencies, ranging from the fundamental power circuit frequency up into the radio frequency band . This EMI creates problem for digital tachometer to show accurate speed reading of the motor. We also observed that at slow speed heat sink heated up quickly. This is because at slow speed i.e. when pulse width of the gate signal of the MOSFET decreases factor (ratio of the a.c components to the average value) also increases and causes the heat sink to heat up quickly. Fluctuations of supply voltage of our machine lab also create problems to control the speed of motor exactly.

Conclusion

A project can open the door of knowledge for a particular topic. It introduces a student to work in practical field. We got such kind of a project “Speed control of a DC motor with the aid of computer’s parallel port” which introduced us with the controlling of a DC motor in a programmable manner as well as visual basic programming language. We saw that there is a difference between theoretical design and practical implementation. This is due to the inherent properties of the circuit equipments. Finally, we can say that this practical work will help us in our working field.

Submitted By MD. SOHAG RANA and MD. RAKIBUL ISLAM

0 comments:

Post a Comment

Please wait for approval of your comment .......