Power Semiconductor Devices

Latest Post

Familiarization with the IGBT Chopper/Inverter module

Familiarization with the Chopper/Inverter Control Unit (Inverter Modes)

CHOP. PWM- Pulse-width modulation (PWM) control chopper

CHOP. STEPS- Two-step control chopper

3~ 120˚- 120˚-modulation three-phase inverter

3~ 180˚- 180˚-modulation three-phase inverter

3~ P1- Programmed-waveform 1 modulation three-phase inverter

3~ P2- Programmed-waveform 2 modulation three-phase inverter

3~ V/f- Constant V/f ratio three-phase inverter

2~ 180˚- 180˚-modulation two-phase inverter

AUX.- Auxiliary

Familiarization with the Chopper/Inverter Control Unit (Chopper Modes)

OBJECTIVE

To learn how to use the Chopper/Inverter Control Unit in the various chopper modes.

DISCUSSION

Introduction

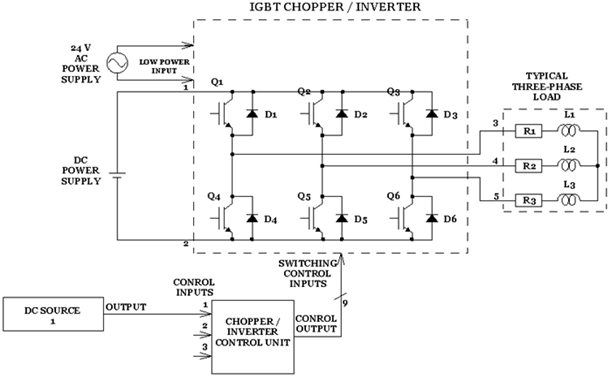

The Chopper/Inverter Control Unit, whose front panel is shown in F5-1, is a control element which is especially designed to build two major types of power electronic circuits: choppers and inverters.

There are ten modes in which the Chopper/Inverter Control Unit can operate. These modes are listed below.

OFF-Standby

CHOP. PWM-Pulse-width modulation (PWM) control chopper

CHOP. STEPS-Two-step control chopper

3- 120˚-120˚-modulation three-phase inverter

3- 180˚-180˚-modulation three-phase inverter

3-P1-Programmed-waveform 1 modulation three-phase inverter

3-P2-Programmed-waveform 2 modulation three-phase inverter

3-V/f-Constant V/f ratio three-phase inverter

2-180˚-180˚ -modulation two-phase inverter

AUX.-Auxiliary

In the OFF mode, the Chopper/Inverter Control Unit runs in a standby condition where it generates no control signals. Notice that the Chopper/Inverter Control Unit also runs in the standby condition in the AUX. mode. This mode is kept available for future developments.

The Pulse-Width Modulation (CHOP. PWM) and two-step control (CHOP.STEPS) modes of the Chopper/Inverter Control Unit are used to build various types of choppers. These modes are dealt with in this section.

Six other modes of the Chopper/Inverter Control Unit, that is 3--120˚, 3--180˚, 3—P1, 3—P2, 3—V/f and 1--180˚, are used to build various types of choppers.

The front panel of the Chopper/Inverter Control Unit is divided into five sections which are described in the following subsections.

F5-1: Front panel of the Chopper/Inverter Control Unit.

The MODE section

This section allows the mode in which the Chopper/Inverter Control Unit operates to be selected. The OFF MODE is automatically selected when the module is powered up. Successive modes in the list shown on the front panel of the module are selected when the SELECT. push button is brifly depressed. The selected mode enters into operation only after a delay of approximately 2 seconds. A LED in the MODE display light up to idicate the selected mode. Notice that the OFF MODE is selected when the SELECT. push button is depressed during more than approximately 0.5 second.

The CONTROL INPUTS section

This section consists of three inputs which can receive signals whose voltage can vary from -10 to +10 V. these inputs are numbered 1, 2 and 3. The function assigned to each input depends on the mode in which the Chopper/Inverter Control Unit operates. The function assigned to each input, depending on the operating mode of the Chopper/Inverter Control Unit, is described further in this discussion.

The CONTROL OUTPUT section

The 9-pin connector of this section provides control signals (pulse signals) which are used to switch power transistors on or off, such as those in the MOSFET Chopper / Inverter module. These control signals can also be used to trigger power devices such as the thyristors in the Power Thyristor module.

The pin configuration of the CONTROL OUTPUTS connector is same as shown in F2-3. Pins 1 to 6 provide 0-5 V level signals for controlling power devices Q1 to Q6 of power modules such as the MOSFET Chopper / Inverter or the Power Thyristors. Pin 7 provides a synchronization signal which is useful to synchronize the oscilloscope when observing the control signals. Pins 8 and 9 are connected to the common point of the Chopper/Inverter Control Unit.

The DC SOURCE 1 and DC SOURCE 2 section

Each of these sections provides a dc voltage which can be set between -10 and +10 V. Each of these voltages can be injected into one of the CONTROL INPUTS of the module, where it controls a given parameter. The nature of this parameter depends on the mode in which the Chopper/Inverter Control Unit operates. The OUTPUT voltage is -10 V when the control knob is set to min. position. The OUTPUT voltage is +10 V when the control knob is set to MAX. position.

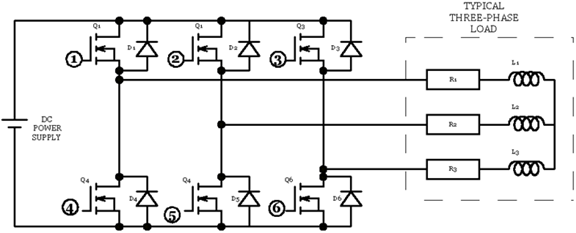

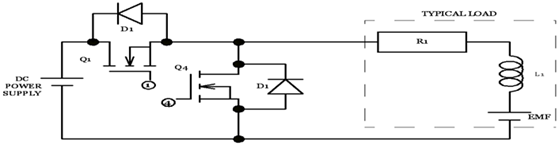

The PWM-control chopper MODE (CHOP. PWM)

In this mode, the Chopper/Inverter Control Unit generates pulse-width modulation (PWM) signals designed to control a chopper. In this case, the chopper is pften referred to as a PWM-control chopper. F5-2 shows the schematic diagrams of various types of choppers built with power MOSFETs. Notice that the gate of each MOSFET is left open in this figure. Each gate only needs to be connected, through an isolator and an amplifier, to an appropriate control circuit, such as the Chopper/Inverter Control Unit, to complete the schematic diagram of each chopper.

a) A BUCK CHOPPER

b) A BOOST CHOPPER

c) A BUCK/BOOST CHOPPER

d) A FOUR-QUADRANT CHOPPER

F5-2: Schematic diagrams of various types of choppers built with power MOSFETs.

F5-2 shows an example of the PWM control signals which the Chopper/Inverter Control Unit generates in the CHOP. PWM MODE. These signals, which are numbered 1, 2, 4 and 5, can be injected, through isolators and amplifiers, into the MOSFET gates bearing the same number in the schematic diagrams of choppers shown in F5-2. In brief, one or many of these signals are used, according to the type of chopper, to switch the MOSFET on and off and deliver a certain amount of power to the load. Varying the duty cycle of the PWM control signals allows the amount of power delivered to the load to be varied. The duty cycle is defined as the ratio of the pulse duration to the duration of one cycle of the pulse signal. Note that PWM control signals 1, 2, 4 and 5 are available on pins 1, 2, 4 and 5 of the CONTROL OUTPUTS connector, respectively.

F5-3: PWM control signals generated by the Chopper/Inverter Control Unit in the CHOP.PWM MODE.

The duty cycle and frequency of the PWM control signals can be varied using CONTROL INPUTS 1 and 2, respectively. The duty cycle of PWM control signals 1 and 5 varies linearly from 0.05 to 0.95 as the voltage applied to CONTROL INPUT 1 varies linearly from -10 to +10 V. Conversely, the duty cycle of PWM control signals 2 and 4 varies linearly from 0.95 to 0.05 as the voltage applied to CONTROL INPUT 1 varies from -10 to +10 V. The frequency of the PWM control signals varies linearly from 100 Hz to 2kHz as the voltage applied to CONTROL INPUT 2 varies from -10 to +10 V. CONTROL INPUT 3 is not used in the CHOP. PWM MODE.

The two-step control chopper MODE (CHOP. STEPS)

In this mode, the Chopper/Inverter Control Unit acts as a controller for a two-step neutral-zone control system, which is sometimes referred to as a bang-bang control system. A two-step neutral-zone control system is a closed-loop control system; there is a reference signal, a feedback signal and an error signal. The controller in a two-step neutral-zone control system sends an on/off signal to the device which operates on the variable under control, so that the value of this variable remains between two predefined values, which are often referred to as set points. Therefore, the error on the controlled variable remains in a certain range of values, which is referred to as the neutral zone.

For example, a two-step neutral-zone controller, such as the Chopper/Inverter Control Unit used in the CHOP. STEPS MODE can be used to switch the transistor(s) in a chopper on and off so that the instantaneous voltage, current, temperature etc., remains within two given set points. F5-4 shows an example of the signals generated in such a circuit when the variable under control is voltage. As can be seen, the control signal generated by the Chopper/Inverter Control Unit change state when the instantaneous voltage reaches the lower and upper set points. This makes the error signal that is the difference between the reference voltage (reference signal) and the instantaneous voltage (feedback signal), remain in the neutral zone defined by the two set points. Notice that the control signals generated by the Chopper/Inverter Control Unit, which are numbered 1, 2, 4 and 5 can be injected through isolators and amplifiers into the MOSFET gates bearing the same number in the schematic diagrams of choppers shown in F5-2. These control signals are available on pins 1, 2, 4 and 5 of the CONTROL OUTPUTS connector, respectively.

In the CHOP. STEPS MODE. CONTROL INPUTS 1 and 3 are used to inject the reference and feedback signals, respectively, into the Chopper/Inverter Control Unit. Voltages varying between -10 and +10 V can be applied to CONTROL INPUTS 1 and 3. CONTROL INPUT 2 allows the range of the neutral zone to be set. This range is equal to one half the absolute value of the voltage applied to CONTROL INPUT 2. This voltage can be varied between 0 and ±10 V.

Let us consider an example where the voltage applied to CONTROL INPUTS 1 and 2 are equal to +7 V and 3 V, respectively. This sets the reference signal to +7 V and the range of the neutral zone to 1.5 V (3 V÷ 2). Since the range of the neutral zone straddles the reference signal, the upper set point is at +7.75 V (7 V + 0.75 V) and the lower set point is at +6.25 V (7 V – 0.75 V).