previous CONCEPTS OF METERING FLUID FLOW

OSCILLATING PISTON AND NUTATING DISK METERS

(c) Check for adequate supply of meter connection gaskets.

(d) Ensure that location of meter provides protection from frost, traffic, or other hazards that may be present.

(e) Ensure that installation is in accordance with direction-of-flow markings on the meter maincase.

(f) For optimum performance, ensure that meter is positioned in a horizontal plane.

1. Monthly Inspection: In addition to any instructions provided by the manufacturer, inspect meters monthly for the following conditions:

(a) Meter is operating.

(b) Noisy operation (repair or replace meter as required).

(c) Leaks (repair as needed).

(d) Cleanliness of glass cover on register dial (clean as needed).

2. Annual Inspection: In addition to the inspections in paragraph 4.1, inspect meters annually for the following conditions:

next COMPOUND WATER METERS

OSCILLATING PISTON AND NUTATING DISK METERS

Oscillating piston and nutating disk are the most common type meters used for residential water service. They are essentially equal in performance and have an excellent combination of accuracy, long life, simple design, moderate cost, and ease of maintenance.

1. Oscillating Piston Meters

1.1 Meter Design--Oscillating piston meters (Figure 4-1) are available in nominal sizes up to 4 inches , with a maximum capacity of 500 gallons per minute. The operating and physical characteristics of these meters are listed in tables 4-1 and 4-2. This type of meter is commonly used for measuring cold water, but models are available for use with fuel oils and liquified petroleum gas (LPG).

1.1 Meter Design--Oscillating piston meters (Figure 4-1) are available in nominal sizes up to 4 inches , with a maximum capacity of 500 gallons per minute. The operating and physical characteristics of these meters are listed in tables 4-1 and 4-2. This type of meter is commonly used for measuring cold water, but models are available for use with fuel oils and liquified petroleum gas (LPG).

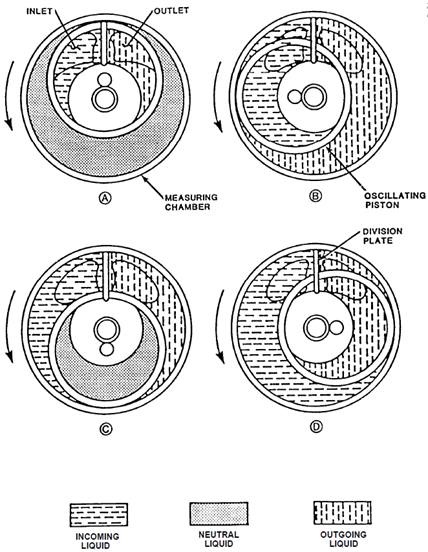

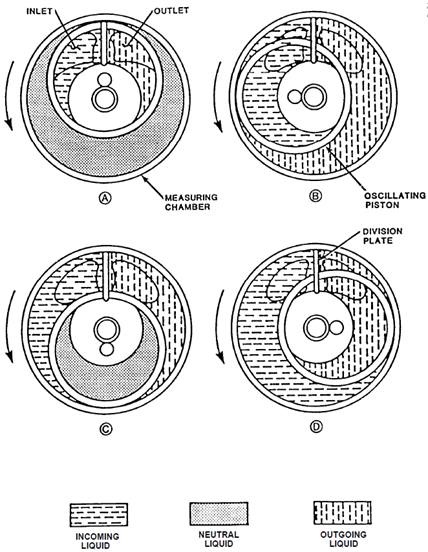

1.2 Operating Principles--The main components of an oscillating piston meter are maincase, measuring chamber, and register. As liquid flows through the meter strainer and into the measuring chamber (Figure 4-2) it drives the piston. The piston oscillates around a central hub, guided by the division plate. The motion of the oscillating piston is transferred to a magnetic assembly in the measuring chamber, which drives a follower magnet. The follower magnet drives the register geartrain, which translates the number of piston oscillations into units of total volume that are displayed on the register dial. The unit of measurement must be specified as either gallons, liters, cubic feet, or cubic meters.

2. Nutating Disk Meters

2.1 Meter Design-Nutating disk meters (Figure 4-3) are available in nominal sizes up to 6 inches, with a maximum capacity of 1,000 gallons per minute. The operating and physical characteristics of these meters are listed in tables 4-1 and 4-2. This type of meter is commonly used for q easuring cold water, as well as chemical additives and mixture ingredients,

2.1 Meter Design-Nutating disk meters (Figure 4-3) are available in nominal sizes up to 6 inches, with a maximum capacity of 1,000 gallons per minute. The operating and physical characteristics of these meters are listed in tables 4-1 and 4-2. This type of meter is commonly used for q easuring cold water, as well as chemical additives and mixture ingredients,

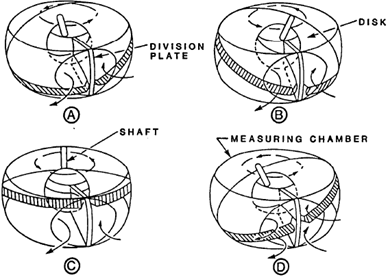

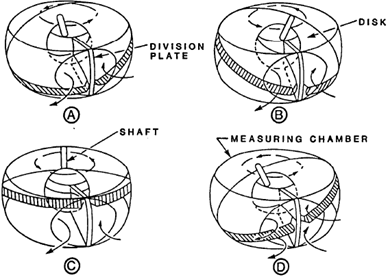

2.2 Operating Principles--The basic components of a nutating disk meter are maincase, measuring chamber, and register (Figure 4-3). As liquid flows through the meter strainer and into the measuring chamber it drives the disk (Figure 4-4). Movement of the liquid around the measuring chamber, first above and then below the disk, imparts a nutating motion to the disk (nodding in a circular path without revolving about its own axis). A shaft that is perpendicular to the disk extends from the top of the central ball of the disk. As the disk nutates, the top of the shaft moves in a circular path and, by engaging a crank, operates the meter register. The unit of measurement must be specified as either gallons, liters, cubic feet, or cubic meters.

FIGURE 4-1. Oscillating Piston Meter With Inlet and Outlet Valves

LIMITATIONS: Rated maximum capacity for oscillating piston and nutating disk meters is shown in Table 4-1. Normal flow for these meters should not exceed approximately one-half of maximum capacity. Operating at maximum capacity-should be limited to short periods or peak loads occurring after long intervals. Maximum pressure loss for both types is from 8.5 to 10.0 percent of maximum operating pressure as shown in Table 4-1. Mechanical drive and some magnetic drive meters have two changeable gears in the geartrain. Changing one or both of these gears allows the ratio between the motion of the piston or disk and the register to be calibrated for maximum accuracy of registration. When used for cold water service, the turndown ratio for these heaters is approximately 80:1, depending upon manufacturer, model, and size. Other limitations are as follows:

- Temperature limit is 80°F.

- Pressure limit is 150 psig.

- Installation is permanent.

TABLE 4-1. Operating Characteristics

Oscillating Piston and Nutating Disk Meters

TABLE 4-2. Physical Characteristics*

Oscillating Piston and Nutating Disk Meters

FIGURE 4-2. Operating Cycle, Oscillating Piston Meter

FIGURE 4-3. Magnetic Drive, Nutating Disk Meter

FIGURE 4-40 Operating Cycle, Nutating Disk Meter

INSTALLATION: Oscillating piston and nutating disk meters must be installed in the flow line, upstream of the activity or outlet they are monitoring. These meters do not require any minimum length of straight pipe be installed before or after the meter. When installing a meter, be sure the following checks have been made and the indicated items are available.

(a) Check for meter shutoff valve on inlet side of meter.

(b) If extensive line drainage is anticipated, a shutoff valve may be installed on the outlet side of the meter.(c) Check for adequate supply of meter connection gaskets.

(d) Ensure that location of meter provides protection from frost, traffic, or other hazards that may be present.

(e) Ensure that installation is in accordance with direction-of-flow markings on the meter maincase.

(f) For optimum performance, ensure that meter is positioned in a horizontal plane.

If remote reading or electronic transmitting devices are used, install in accordance with chapter 10 and the manufacturer’s instructions.

MAINTENANCE: The following inspection schedules are adequate for average installations.1. Monthly Inspection: In addition to any instructions provided by the manufacturer, inspect meters monthly for the following conditions:

(a) Meter is operating.

(b) Noisy operation (repair or replace meter as required).

(c) Leaks (repair as needed).

(d) Cleanliness of glass cover on register dial (clean as needed).

2. Annual Inspection: In addition to the inspections in paragraph 4.1, inspect meters annually for the following conditions:

(a) Cleanliness of meter box, housing, or pit (clean as needed).

(b) Adequate protection from freezing (provide protection at least 1 q onth prior to start of the season).

(b) Adequate protection from freezing (provide protection at least 1 q onth prior to start of the season).

3. Periodic Inspection: Periodic inspection of meters is required to determine whether they are measuring accurately. The time between inspections should be based on local conditions and the amount of use. The manufacturer’s representative in any particular area should be familiar with local conditions and capable of assisting in the preparation of a schedule for periodic inspection of meters.

ACCURACY: Accuracy limits for water meters have been established by industry. For the meters discussed in this section, limits are based on tests run at three different rates of flow; maximum, intermediate, and minimum. The accuracy limits for the maximum and Intermediate rates are from 98.5 to 101.5 percent of the quantity measured. The limits for the minimum rate are from 95 to 101 percent.next COMPOUND WATER METERS

Thanks for sharing this Article and here is some information about Domestic House hold Water Meters .

ReplyDeleteThanks for sharing this Article and here is some information about Digital Water Meters.

ReplyDelete