previous METER INSTALLATION

DATA FROM DEMAND SURVEYS: Electric bills may provide only the peak demand for a month or the average of three or four highest peaks for a month, depending on how the particular utility company computes maximum billing demand. No indication is given of how this peak compares to the balance of the demand profile for the interval, nor what combinations of loads caused the peak. This information can only be acquired by monitoring key points in the internal electrical system.

1. System Information: Each electrical system is different, but system information for each follows a similar pyramid pattern, with overall system information available at the peak and an increase in detailed information available as the base is approached. Figures 9-15, 9-16, and 9-17 illustrate the process of demand surveying in three phases.

2. Survey Starting Point: The survey should begin at the utility service entrance. If a pulse initiator is in place, a demand analyzer can be connected without need for voltage or current connections. If a pulse initiator is not installed, additional connections will be required. Consult the user manual for the demand analyzer before making any connections.

2.1 Utility Service Entrance: A utility service entrance demand profile gives considerable information about the overall system. Comparing profiles obtained from system monitoring will provide answers to the following questions and will prove valuable in analyzing an electrical system.

- What is the peak facility load in kilowatts?

- What day of the week did it occur?

- Was the peak the same each day? If not, why?

- What is the after-hours load? Was it the same each day/night?

- Is there evidence of power wasted by starting equipment before hours or letting it run unnecessarily during lunch or after hours?

- HOW does the peak compare with the utility company’s demand charge for the previous month?

- Could a slight change in startup time save money?

- HOW long did it take the facility to reach full power load after starting time?

- Is there a tendency to anticipate quitting time?

- What is the maximum power factor of the load? What is the minimum?

- When did the minimum power factor occur? What caused it?

- How does the power factor compare with the one on which the previous power bill was based?

- What is the voltage drop between the main power bus and the various major consumers.

FIGURE 9-15. Demand Survey, Phase I

FIGURE 9-16. Demand Survey, Phase II

FIGURE 9-17. Demand Survey, Phase III

If the profile peaks radically at only a few points, then demand leveling could lead to a reduction in demand charges. An exception to this may exist because of peaks caused by individual pieces of equipment, or allied pieces, that must operate together. It may be preferable for the equipment use to be shifted to a reduced-demand charge period. If the demand profile is reasonably level, it may indicate that reduction of demand charges can only be obtained through planned reduction in total consumption.

3. Specific Load Profiles: The next step in a demand survey is to record electrical power consumption by substation, building, and department. This enables the facility engineer to associate some of the causes of the undesirable conditions with more specific load profiles. Some information obtained from recording instruments at the building level will provide answers to the following questions.

- Did the building equipment start on time in the morning and after lunch?

- What is the load at noon and night?

- How long did it take for the building and each department to reach full power load after startup?

- To what extent was quitting time anticipated at noon and in the evening? Were machines left running idle?

- What is the idle load in the building?

- Does the building have a peak load that corresponds to the total facility peak? What causes it? Could a change in scheduling reduce the power demand?

- Is there evidence of pyramiding loads which cause excessive or pulsating peaks?

- Does anything in the record offer explanations as to the waste of power?

- What proportion of the demand charge and energy consumption should be allocated to this building?

- What is the power factor?

4.1 Equipment Monitoring: If electrical power consumption is excessive, the equipment may be overloaded or faulty. If equipment is drawing more current than expected, it may indicate the need for a more efficient motor. Answers to such questions are especially informative in interpreting performance of automatically-operated equipment. The record shows when and how long each machine was operated and how long it was idle. It discloses waste if automatic equipment is not functioning properly. Monitoring individual equipment will answer the following questions;

- (a) What are maximum, minimum, and average loads for the equipment? Are they within specifications?

(b) If the motor is not the correct size, what is the horsepower of the motor that should replace it?

(c) Is there sufficient voltage at the motor terminals?

(d) How much does the unit contribute to peak load?

(e) Could the equipment schedule be rearranged to reduce peak load?

(f) Is load on a unit a contributor to any loss of productive effort shown by the department record?

(g) What is the idle load of this unit?

(h) Does the idle load show any marked increase since the last survey?

(i) Does the record show any characteristic which indicates a faulty condition in the motor or the associated equipment?

(j) How does the record compare with other records of similar equipment?

(k) Does the record show any data valuable in reducing energy consumption?

INTERNAL SURVEYS: Assuming that improvements seem possible, then further investigation must be carried out to determine what load makeups are causing the demand peaks and what can be done to shift load combinations to reduce these peaks.

1. Demand Survey Example: Each electrical system is different, but they all spread out like a pyramid, with total facility information available at the peak and more detailed information available as the base is approached. At whatever point a demand analysis is made, it must be carried out for a full cycle of operations so that normal permutations and combinations of loads are encountered. Depending on the facility, a full cycle may be a day, but more likely a week, and sometimes a complete month or billing period is required. Figure 9-18 shows a typical situation with three substations and three feeders per substation. The survey should begin at the utility service entrance.

1.1 Service Entrance: A utility service entrance demand profile gives considerable information about the overall plant. If it peaks radically at a few places then demand leveling could lead to a reduction in demand charges, unless the peaks are being caused by individual or allied pieces of equipment which must operate together. It may be profitable to shift these loads to a reduced demand charge offpeak period, if the rate schedule includes such time-dependent provisions. If the demand profile is reasonably level, it may indicate no need for load shifting.

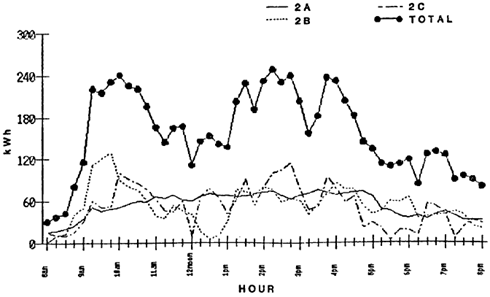

1.2 Substation and Feeders: In Figure 9-18, the demand of the three substations and the individual feeders supplied by the substations are monitored. Provided that the demand studies are carried out at comparable times in the plant operating cycle, and that successive operating cycles show reasonable consistency, the three substation demand profiles should be roughly equal to the overall plant profile. The sum of the individual feeder profiles should roughly equal the respective substation demand profile. Figure 9-19 shows this concept for substation No. 2 and feeders 2A, 2B, and 2C. These plots were obtained on four successive Wednesdays from data obtained by monitoring the three feeders and the substation output from 8:00 AM to 8:00 PM.

FIGURE 9-18. Three Substations With Three Feeders Per Substation

1.3 Profile Analysis: In Figure 9-19 the peak demands occur around 10:00 AM and during the period from 1:00 PM to 5:00 PM. After the morning buildup, feeders 2A and 2C show level demand, with the substation peaks being principally caused by erratic loading of feeder 2B. If the demand on feeder 2B is made up of many small loads, then a better time distribution of these loads would level demand on this feeder and consequently on substation No. 2. Other possibilities are to shift loads on feeders 2A and 2C away from the peaks of feeder 2B, or to transfer some of the peak loads on any of the feeders to second shift. If these steps are not possible, then the peaks from this substation could be mated to the valleys from other substations.

1.4 System Management: Developing a series of plots for an entire facility and designating the principle loads on the plots, gives a clear picture of the overall demand situation, building from the base of the pyramid to the peak. Such information is invaluable in developing procedural steps that reduce demand charges or developing an energy management system program.

2. Periodic Studies: It is important to remember that changing market forces and equipment requirements create needs to modify a system load makeup. Therefore, periodic studies should be carried out, at least at the utility service entrance, to make sure that gains from a previous energy audit are not outdated.

FIGURE 9-19. Demand Profiles

next INSTRUMENTATION IN METERING

0 comments:

Post a Comment

Please wait for approval of your comment .......