previous ELECTRICAL ENERGY SURVEYS

Today’s versatile electronic instrumentation allows managers to manage their systems 24 hours a day without using meter readers. The old method of collecting data using meter readers, who periodically inspect and log readings for strategic meters, creates a reaction delay to situations that should be corrected immediately. For instance, in the event of a line break, modern instrumentation would report the leakage upon occurrence as opposed to later discovery by a meter reader. An instrument alerts the operator that an excessive flow is passing through the system and the manager can then take immediate action. The meter can record the time and magnitude of the leakage, actuate alarm systems, and provide a variety of signals to initiate corrective action. In addition to providing-information on occurring events, electronic instrumentation provides records for later viewing to analyze trends or significant changes or billing information.

1. Operating Principles: An electronic instrument records the amount of a media passing through a meter and converts it into an electrical signal to be displayed in meaningful units. Other equipment can be controlled based on this signal. Consumption registered on an electromechanical or electronic totalizer shows the amount of the media that has passed through the meter over a period of time. Quantity may be displayed in a variety of units, not necessarily those displayed on the meter register. A second common instrument display is the instantaneous rate through the meter.

1.1 Meter Output: The output is typically shown on an analog (a needle and scale instantaneous reading meter) or digital (a digital readout meter reporting in discrete scale increments) indicator. Output may also be fed to a variety of chart recorders for permanent records.

1.2 Meter Signals: Along with the basic outputs, modern processors are able to provide a variety of signals for use with computers and other process management equipment. Some examples of output signals are: 4-20 mA, 2-10 VDC, O-5 VDC, and 3-30 VDC pulse. If the data is to be entered into a computer system, an interfacing module can prepare the data signal for an RS-232C input application. These signals offer an infinite variety of system control functions and can provide data readouts to both local and remote locations. The receiving equipment is able to convert the data received from a simple slave device into a base for a complete management system.

2. Local Instrumentation: Figure 10-1 shows a meter sending an electronic signal to a local instrument that displays the instantaneous use rate on an analog indicator and the total use measured on a totalizer. The analog use rate indicator may be replaced with a digital indicator or a variety of recording devices, if desired.

2.1 Meter With Onsite Recorder: Figure 10-2 shows an equivalent package with a 31-day strip chart recorder that replaces the analog indicator of the system in Figure 10-1. This configuration is used when data is required at close intervals and no other data or functions are required of the metering operation. This arrangement would be useful to the onsite operator who requires an Immediate data record.

FIGURE 10-1. Meter With Onsite Monitoring

FIGURE 10-2. Meter With Onsite Recorder/Totalizer

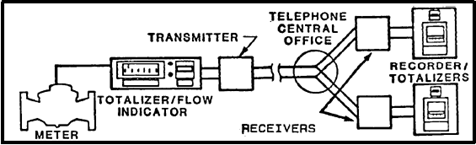

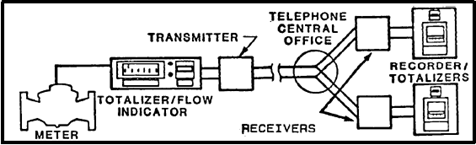

3. Remote Instrumentation: With the advent of inexpensive PCS, software, and new meter technologies, most utilities management functions can be automated within the foreseeable future. Meter data may be transmitted to remote locations by adding a transmitting option and the appropriate transmission equipment to the metering system. The transmission distance is limited by the equipment and the availability of a communications link between the meter site and the remote location. Figure 10-3 shows an expansion of figure 10-1 with the meter-generated data being displayed onsite and also being transmitted via the telephone system to a remote point that may be many miles from the meter site. If information is not required onsite, the onsite instrument can be replaced with a transmitting module as shown in Figure 10-4. Transmitted data can be analyzed automatically using specially adapted PC software, and reports such as the Utilities Cost Analysis Report (UCAR) and the Defense Energy Information System (DEIS) II Report can be generated and transmitted automatically. Because of the cumbersome nature of present systems of meter reading, recordkeeping, billing, and reporting, very little analysis is performed. Modernizing the way utilities are managed will save money, improve readiness, and provide better support to the fleet.

Remote monitoring technology will enable a utilities mangement system that will automatically record metered consumption data for major utilities at an activity and send data to a central PC. The PC will receive the data, and automatically generate utility bills for tenants. In addition, remote monitoring equipment installed at major steam, electric, compressed air, and chilled water generating plants will provide detailed information on equipment status and performance. This data, along with utility company cost and consumption data, operations and maintenance personnel cost data, material cost data, and other information, will be used to automatically generate various analyses of utilities costs and performance. These analyses will allow managers to make decisions that will result in optimized operations in the present and future.

3.1 Remote Interfacing Kilowatt Meters: There are two reasons for providing a kilowatthour meter with a pulse initiator. The pulse initiator allows for monitoring of the load center on a temporary basis or collecting remote data on a permanent basis. In either case, pulse initiators are manufactured with a variety of output signal parameters and care must be taken to ensure compatibility of components. For applications requiring a distance between the pulse device and data collection point of over 50 feet, the signal may require reinforcement. Increased voltage and the use of signal repeaters are two common methods used. Do not attempt any signal manipulation without first referring to the manufacturer’s instructions of all equipment involved.

3.2 Transmission to TWO Points: The need to have data transmitted to two remote points is frequently necessary in the wholesaling or custody transfer of the commodity. In these applications, both the supplier and the end user must have meter data readily available to them. Figure 10-5 depicts a means of accomplishing the task with one telemetry transmitter. Figure 10-6 shows a system with two data channels if the channels must be isolated.

3.3 Repeater Transmission: Repeater data transmission systems provide the user with a relatively inexpensive means of sending data to a remote point, as shown in Figure 10-7. Although repeaters accomplish the transfer of data from local to remote points at a cost of approximately 10 percent of what other transmission systems cost, they do have limitations. The primary consideration when a repeater is contemplated is its requirement for a dedicated wire pair. When using a repeater, no other signals may be on the wire pair. Repeaters also have finite distance limitations, usually expressed in ohms rather than distance, because the gauge of transmission lines varies. Typically, a repeater system is limited to a maximum transmission loop resistance of 4,000 ohms. Another means of data transmission is the use of a modem through existing telephone lines which is cost effective since the cost is only the price of a telephone call.

4. Computer Management: The system shown in Figure 10-8 usually requires telemetry of data from a number of meters in a system, to a central point where the data is converted into a computer compatible signal (RS-232C). In this system, the computer continuously monitors the data lines. It immediately warns the operator when a signal is not within programmed limits.

FIGURE 10-3. Onsite and Remote Monitoring

FIGURE 10-4. Metering System With Interface Module

FIGURE 10-5. Single Transmission Split in Communication Link

FIGURE 10-6. TWO Transmission Modules--Two Data Channels

FIGURE 10-7. Extended System Using a Repeater

FIGURE 10-8. Multi-Input System

FIGURE 10-9. Chart Recording System

On demand, the computer prints a complete analysis of the system and output totals to present. When strategically located meters are connected to a computerized system with critical parameters, the computer can instantaneously provide the information necessary to monitor, control or operate a system.

5. Demand Billing: As the cost of energy, materials, and labor increases, there is a need to limit the large, intermittent demands on systems and to encourage utilization during offpeak periods. To accomplish this task and identify systems not in conformity with policy, instrumentation is required.

5.1 Control Parameters: Control parameters depend on the characteristics of the system. Some systems are limited in peak capacity and must control maximum use. There may be other areas of concern that are unique to a particular system, such as a user who intermittently uses power at a rate that overloads the system, affecting many other users.

5.2 Recorder Types: Common instruments used in a demand billing system are a rate recorder such as the one illustrated in Figure 10-2, or a circular recorder, as shown in Figure 10-9. Circular recorders are not highly effective if data reduction is required and have been replaced with a data logger with reduction by microprocessor program. These devices record the use rate continuously. Peaks are easily detected over the period of recording. If a recorder is used, the preferred type is a linear tracking, multichannel recorder. One advantage of this system is that the chart becomes a permanent record in case of customer disagreement concerning subsequent billings.

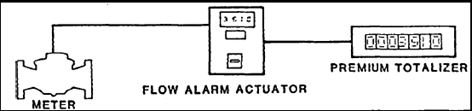

5.3 Alarm Actuator: A unique variation of chart recorders is shown in Figure 10-10. In this application the utility installs an instrument with a recorder onto user equipment. The agreement with the user is that severe penalties will be levied each time the use exceeds a predetermined rate. In an effort to avoid the penalty, a two-point alarm actuator is installed with an alarm programmed to respond at some warning point before the limit is reached, and then to initiate action if the limit is exceeded.

5.4 Alarm With Totalizer: Another variation of a use rate and penalty system is shown in Figure 10-11. This approach places a penalty (generally a unit price increase) on all consumption exceeding the limit. This is accomplished by employing an alarm actuator and using a totalizer to record the excessive usage.

SYSTEM COMPONENTS: 1 Meter Energy Usage. Although each medium requires a specific type of meter, all meters must have a signal-generating device to provide either onsite or remote data reading and recording capabilities. The meter must sample the media and transmit a representative signal to the system. Electric meters rely on the medium they monitor for energy to produce the monitoring signal. Turbine meters generate their own signal. Many meters rely on an outside source of electricity to produce a transmission signal.

FIGURE 10-10. Alarm Actuator System

2. Signal Generators: Electronic or electromechanical signal generators are available that produce analog and/or digital signals for transmitting data to data processing equipment (onsite meters or recorders) or to a more complex remote system.

2.1 Analog Output: The analog output of a signal generator is a continuous signal representing the quantitative information obtained by the meter.

2.2 Pulse Output: A pulse output is a discrete series of pulses produced by the signal generator representing quantitative information.

3. Power Supply: Power supplies are a required part of many systems to supply low voltage in direct current (VDC) and low current in milliamperes (mA) for excitation of the signal generator. The low voltage and current is processed by the signal generator, producing an analog and/or digital signal, for transmission to the monitoring system.

4. Pulse Rate Converter: The pulse rate converter (PRC) is designed to interface between the meter pulse generating unit and measuring equipment. The device accepts low-level input frequency signals, processes the signals, and provides output signals that are proportional to the use rate.

5. Pulse Compensator: Pulse compensators are self-contained electronic modules which compensate the output pulse train of a meter with respect to a secondary process variable such as temperature, pressure, or density.

6. Frequency-to-Current Converter: The frequency-to-current converter (FCC) converts the pulse output from a meter or other transmitter into a proportional 4-20 mA current loop signal.

FIGURE 10-11. Alarm Actuator and Totalizer System

7. Repeater: The repeater is used to extend the distance the remote equipment can be located from the meter. The repeater is located as close as practical to the meter. The repeater allows reduction of the electrical load on the meter generator electrical contacts, extending the life of the device. It also provides a strong signal to allow monitoring equipment at remote locations to be as much as several miles from the meter.

8. Accumulators: When it becomes necessary to place two or more meters in parallel to satisfy a system requirement, an accumulator collects and combines data from these meters and transmits a totalized signal to the remainder of the system.

0 comments:

Post a Comment

Please wait for approval of your comment .......