previous METERS AND SUPPORT DEVICES

where:

kW = kilowatt Demand

n = number of pulses occurring over the counting interval

KWC = constant number of kilowatts per pulse (demand multiplier)

T = counting interval in hours

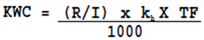

KWC, the watthour constant of the pulse devices, is calculated by:

where:

R/I = number of revolutions of the rotor per pulse. This is a constant provided by the manufacturer of the pulse device.

TF = transformer factor = CT ratio x PT ratio

kh = watthour constant

Two types of pulse devices are in common use, contact and pulse initiator.

For single-phase transformers or loads, multiply the above three-phase values by 1.73.

Example 1: A 5 kVA single-phase transformer has a secondary line current of 12 x 1.73 = 20.8 amperes at 240 V when operating at full load.

OTHER ELECTRICAL METERING COMPONENTS

1. Pulse Device (Digital): A widely used method of demand metering is the block interval, so called because a kWh measurement is totalized over a block of time, typically a 15- or 30-minute period. The most flexible and easily computerized block interval metering technique is pulse totalization. Each pulse represents a specified amount of kilowatt hours read by the meter from total or partial rotation of the disk. A pulse device can be retrofitted to most existing electromechanical watthour meters. These devices cause relay contacts to close at a rate proportional to load on the meter. Defined kilowatt demand is derived from relay closure pulses using the expression:

where:

kW = kilowatt Demand

n = number of pulses occurring over the counting interval

KWC = constant number of kilowatts per pulse (demand multiplier)

T = counting interval in hours

KWC, the watthour constant of the pulse devices, is calculated by:

where:

R/I = number of revolutions of the rotor per pulse. This is a constant provided by the manufacturer of the pulse device.

TF = transformer factor = CT ratio x PT ratio

kh = watthour constant

Two types of pulse devices are in common use, contact and pulse initiator.

1.1 Contact Devices: A contact device is entirely mechanical, consisting of a multilobed cam, connected into the watthour geartrain. The cam actuates one or more contact sets. All components of the device are mounted on a single backing plate that bolts into the meter mechanism under a glass dome. Three contact configurations are available (Figure 9-12). The different contact devices available service different electromechanical kW demand totalizer configurations. Slow-break contacts, for example, are used for solenoid-operated totalizers and quick-break contacts for motor-operated units. The type of break mechanism is important when contact closures from a pulse initiator are interfaced to a microcomputer through a single digital interface channel. If the sudden drop caused by the cam produces contact bounce, corrective measures must be taken to ensure accuracy of microcomputer displays. High-speed logic circuits are sensitive to contact bounce and are able to resolve a train of pulses from a single bouncing contact switch closure. This problem can be eliminated using software designed to discard any data during a specified period of time following a switch contact.

1.1.1 Contact Device Drives: Most contact initiators are driven by a separate worm gear on the meter shaft. Some meters have up to 360 possible gear ratios using worm gear and sector combinations. Tables for determining equivalent cam teeth (EqT) can be used, given the number of points on a cam and the gear ratio from the meter rotor to the cam. These tables are available from the manufacturer. The disadvantages of contact devices have limited their installation in newer, more sensitive watthour meters. Newer meters produce lower torque per kilowatt and thus are more affected by frictional forces imposed by the cam operated switch. The increased requirement for higher pulse rates and lower spring tension on the contact have proven to increase maintenance problems. Nonmercury-wetted switch contacts experience bounce.

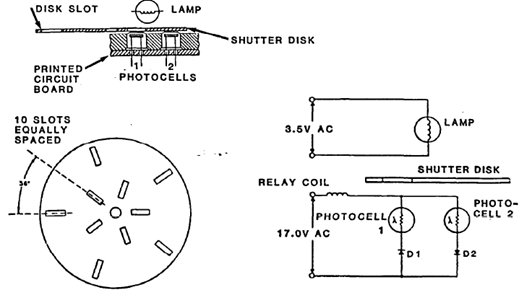

FIGURE 9-12. Contact Device Configurations

1.2 Pulse Initiators: The disadvantages of contact devices are absent in pulse initiator designs. A pulse initiator consists of a revolving shutter disk operated by a standard watthour meter geartrain. The disk, acting as a shutter, interrupts a beam of light to activate a photocell. Figure 9-13 shows the basic configuration of a shutter and the placement of the photocell and light source. The device is essentially frictionless and gives the same switch output as a contact initiator through a mercury-wetted relay. The bounceless contact closure data from pulse initiators are designed to interface with older pulse-totalizing equipment. Pulse initiator modules can be retrofitted to most watthour meters. A typical pulse initiator has one shutter disk with ten slots, producing one pulse per slot. Shutters are available with two, four, six, or eight slots.

FIGURE 9-13. Photocell Initiator

2. Instrument Transformers: To have meters function effectively within their capabilities, current transformers and potential transformers are used. Intended for measurement and control purposes, they perform two primary functions:

- Transform line current or voltage to values suitable for standard instruments which normally operate on 5 amperes and 120 volts.

- Isolate instruments and meters from line voltage. To make this protection complete for both instruments and operators, THE SECONDARY CIRCUIT SHOULD BE GROUNDED. For grounding , see IEEE Standard 52, Application Guide for Grounding of Instrument Transformer Secondary Circuits and Cases.

2.1 Current Transformer: Current transformers (CT) are designed to have the primary winding connected in series with a circuit carrying current to be measured or controlled. The secondary winding will then deliver a current proportional to the line current for operation of meters, instruments, and relays. In cases of portable instrumentation, ammeter and current coils of the wattmeter usually obtain their current signal from a clamp-around current transformer. This CT is used to step down line current to a level that can be conveniently metered, generally to 5 A or less. The CT surrounds the primary conductor and produces a secondary current proportional to the magnetic field created by the primary current in the conductor being measured. The ratio of primary current to secondary current is known as the CT ratio or CTR. CTs are normally rated in values to 5 A such as 100:5, 1000:5, and 5000:5. These values indicate how many amperes flowing in the primary conductor will cause 5 A to flow in the secondary winding. Current transformers must be selected for each application as shown in Table 9-1. In each instance, the secondary winding ratio should result in a secondary output of 5 amps at full-rated primary current. As an example, a 1,000-amp current transformer has a ratio of 200 to 1 and a 50-amp transformer has a ratio of 10 to 1. The secondary of a CT shall always be a complete circuit whenever there is current flowing through the primary conductor. Thus, leads of a CT shall never be fused and shall always be either connected to a low-resistance ammeter movement or shorted together by means of a jumper wire, screw, or switch on a CT shorting terminal strip.

Figure 9-14 is an example of how an ammeter, voltmeter, wattmeter, and a watthour meter may be connected through instrument transformers to a high-voltage line. It is extremely important that manufacturer’s manuals be followed to ensure a proper meter hookup.

FIGURE 9-14. Connection of Instrument Transformers

2.1.1 Mechanical Construction: Current transformers are classified as follows:- Window type: This type has a secondary winding completely insulated and permanently assembled on the core, but has no primary winding. This type of construction is commonly used on 600 volt class current transformers.

- l Bar type: Same as the window type except a primary bar is inserted into the window opening. This bar can be permanently fixed into its position or be removable.

- Wound (wound-primary) type: “This type has primary and secondary windings completely insulated and permanently assembled on the core. The primary is usually a multiturn winding.

2.1.2 Electrical Connection: The following are types of CTs based on electrical connection:

- Single primary: This term is frequently applied to current transformers having a single primary electrical circuit and is generally used to distinguish them from current transformers having series-parallel primary windings.

- Window type with one or more primary turns: A single conductor straight through a window type transformer is a “one turn primary” connection.

If this single conductor is taken through the “window” twice, the nameplate primary rating is reduced by 1/2. (Multiply meter reading by 1/2 the CT nameplate ratio).

If on a single-phase, three wire circuit, two different leads are taken through the same window transformers, the nameplate primary rating is reduced by 1/2 (multiply meter reading by 1/2 the CT nameplate ratio). - Double ratio: Double ratio units are built either with a two-part series parallel winding or with a tap on a secondary winding.

2.2 Potential Transformer: Potential transformers (PT) are designed to have the primary winding connected in parallel with a circuit, the voltage of which is to be measured or controlled. The secondary winding will then deliver a voltage proportional to line voltage for operation of meters, instruments, and relays. A PT is used to reduce line voltage to a level to match the meter rating, generally 120 V. The ratio of primary to secondary voltage is known as the PT ratio or PTR. The leads on a PT shall always be fused and shall never be shorted together. Voltage transformers are available in many accuracy classes; it is important to select one suitable for a specific application. Figure 9-14 shows how a voltmeter would be connected to a potential transformer in a high-voltage circuit. In this instance the turns ratio would be 120 to 1. As with CT hookups, the manufacturer’s manual should be consulted and followed to ensure the meter is properly connected in the circuit.

TABLE 9-1. FULL-LOAD LINE AMPERES FOR THREE-PHASE* TRANSFORMERS OR LOADS

For single-phase transformers or loads, multiply the above three-phase values by 1.73.

Example 1: A 5 kVA single-phase transformer has a secondary line current of 12 x 1.73 = 20.8 amperes at 240 V when operating at full load.

Example 2: Assume the load to be metered is fed by a 500 kVa transformer at 208 volts on the secondary. If the load is metered on the secondary side of the transformer, the ammeter will see a max current of 1,388 amps. Thus a current transformer with a ratio of 400 to 1 (2,000/5) should be used.

2.2.1 Secondary Circuit: Potential transformers are classified by the type of design of the secondary circuit.- Single secondary: In general, standard rating potential transformers, 15 KV class and below, are supplied with a single electrical secondary circuit designed for 120 volts.

- Tapped secondary: There are applications where it is desirable to have two or more values of secondary potential available from the same secondary winding. This is particularly true where it is desirable to connect the secondary winding in delta or wye, for three-phase circuits, and obtain the same secondary voltage.

For such applications, the’ transformer secondary is rated at 120 volts with a tap at 69.3 volts. - Double secondary: Unlike current transformers, double or multisecondary potential,transformers have individual secondary electrical circuits on the common magnetic core. These windings may or may not be tapped. Each secondary is affected by the burden conditions on the other secondaries.

2.3 Transformer Accuracy: Because of the function they perform, all instrument transformers must be classified as to accuracy. The two most important specifications for these transformers are ratio accuracy and phase-angle error. Phase-angle errors should be less than 50 minutes for use with analyzers of the 99 percent accuracy class and 10 min. or less when used with instruments having accuracies of 99.75 percent or better. It is noted that control transformers are not suitable for metering since their voltage can be off by 10 percent.

2.4 Instrument Transformer Polarity: When instrument transformers are used with instruments or relays which operate only according to the magnitude of the current or voltage, the phase position or direction of flow of current is of no consequence; connection to the secondary terminals may be reversed without changing indication of the instrument. When instrument transformers are used with watthour meters, in which the operation depends on the interaction of both current and voltage, the direction of current in the primary and secondary windings must be known. This is indicated by marking one primary and one secondary terminal with a distinctive POLARITY MARKER. When current is flowing toward the transformer in the marked primary lead, it is flowing away from the transformer in the marked secondary lead.

2.5 Grounding: It is always desirable to ground a transformer rated meter and also to ground secondaries of both the current transformer and the potential transformer. This avoids danger of high electrostatic voltages that might otherwise be present as a result of the capacitance (condenser effect) of the potential-transformer windings. This grounding practice also minimizes hazard from high voltages reaching the secondary circuit as a result of insulation breakdown due to lightning surges or other abnormal circuit conditions.

0 comments:

Post a Comment

Please wait for approval of your comment .......