previous CONCEPTS OF METERING ELECTRICITY

where:

Rr = register ratio found on front plate, back plate, or frame of register

Kh = watthour constant

TF = transformer factor = CT ratio x PT ratio

Gr = first gear reduction ratio usually 50 or 100 (obtain from manufacturer)

Self-contained meters, used for domestic service and small industry, usually have a multiplier of either 1, in which case no multiplier would be shown, or 10. Whenever the multiplier is more than 1, the words “multiply by”, followed by a number appear on the front plate. For transformer-rated meters, which are used with instrument transformers for heavy industrial and central station metering, the multiplier can be 10, 100, 1,000, 10,000, etc. In this case the register is supplied for only one transformer factor. The multiplier can also be numerically equal to the transformer factor. If so the register will read in terms of secondary energy and be read on a “secondary-reading register*’. In any watthour meter, the total energy in kWh is equal to the product of the watthour constant (Kh) and the disk revolutions divided by 1,000:

Accurate and reliable data can be obtained using either permanent or portable meters. Permanent meters are generally installed at service entrances and at points of large power demand. To perform a power demand survey, it may be necessary to monitor many additional locations within a system. It may not be economical to install permanent meters at each location, so portable units are used. The cost of portable meters is higher than permanent meters but their accuracy is generally very good.

METERING DEVICES

1. Watthour Meter: Consumption of electrical energy is measured with either a mechanical or electronic watthour meter.

1.1 Mechanical Watthour Meter: A mechanical watthour meter is a small, precision built, induction motor. It consists of a rotating disk, electromagnet, permanent damping magnet, bearings, geartrain, and dial assembly. The electromagnet is wound with a voltage coil and a current coil. When the meter is energized, a small current flows through the voltage coil, connected across the lines, and full load current flows through the current coil. The current in these coils sets up magnetic fields, or magnetic flux that induce small currents (called eddy currents) in the disk. These eddy currents set up their own magnetic field. The combination of fluxes, or magnetic fields, interact with one another in such a manner that the disk is forced to rotate in a positive direction. With voltage and current coils energized, the disk gathers momentum and spins faster. Therefore, a braking device to retard disk speed is provided. The braking device is a permanent magnet through which the disk rotates.

1.2 Electronic Watthour Meter: An electronic watthour meter consists of a current sensor, kilowatt transducers electronic totalizer, and mechanical or electronic digital display. Sensor, transducer, totalizer, and display combinations are available for readings of watthours to megawatthours. As with most electronic power monitoring equipment, the cost is high. Most electronic kWh meters are used in conjunction with computerized energy management systems.

1.3 Watthour Meter Selection Criteria: Some facts that should be known or considered before purchasing and installing a meter are as follows:

- Type of service: single-phase network, 3-wire; 3-phase, 3- or 4-wire; wye (Y) or delta (Δ)

- Circuit voltage: line-to-line or line-to-neutral, depending on meter connections. Determine if requirement exists for PT with current limiting primary fuse.

- Maximum circuit current: assume for current estimating purposes that 1 horsepower = 1 kW = 1 kVA. Determine CT ratio if load is above meter class rating.

- Mounting: socket (S) or bottom-connected (A).

- Register: 4-dial or 5-dial pointer; 4-dial or 5-dial cyclometer; cumulative demand register with 15-minute interval.

- Frequency: check value.

- Compliance to standards: ANSI C12.10, Watthour Meters.

- Special features: pulse device.

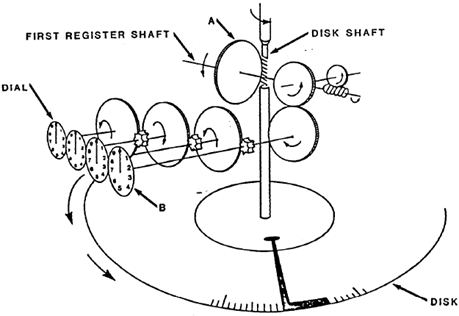

1.4 Watthour Meter Register: A register of a watthour meter is a geartrain designed to count the number of revolutions of the disk (Figure 9-5). Rather than displaying the number of disk revolutions directly, the register derives kilowatthours by the number of disk revolutions. Registers are either pointer type or cyclometer type (Figure 9-6).

1.5 Meter Terminology: To facilitate an understanding of operation, testing, and accuracy of meters, it is helpful to recognize the meaning of certain abbreviations in common use:

Kh = The number of watthours represented by each revolution of the meter disk.

Kr = The register constant. This is the value that a register reading must be multiplied by to obtain the correct kWh registration.

Rr = Refer to Figure 9-5. A ratio of the number of revolutions of first register shaft (A) to each complete revolution of the first pointer shaft (B). The gear marked A is driven by the disk shaft.

Gr = Gear reduction ratio between the disk shaft and the gear (A in Figure 9-5) which meshes with it.

TF = Transformer factor which is the product of the current transformer ratio (CTR) and the potential transformer ratio (PTR).

PKh = Primary meter constant = Kh x TF

1.6 Meter Nameplate: The meter nameplate provides important information in addition to totalized watthours (Figure 9-7).

1.6.1 Class: Modern meters will measure accurately up to 800 percent of full load calibration test amperes. This is denoted by “CL”, or class, on the nameplate. Use Class 20 meters with instrument transformers to obtain straight line accuracy up to 20 amps and also use with CTs with 5 amp secondaries. Class 10 and 20 meters are for use with instrument transformers only . Class 100, 200, and 320 meters are designed to directly meter the line current.

Class 10: 2.5-amp meter with 400 percent overload capability

Class 20: 2.5-amp meter with 800 percent overload capability

Class 100: 15-amp meter with 400 percent overload capability

Class 200: 30-amp meter with 666-2/3 percent overload capability

Class 320: 50-amp meter with 640 percent overload capability

Class 20: 2.5-amp meter with 800 percent overload capability

Class 100: 15-amp meter with 400 percent overload capability

Class 200: 30-amp meter with 666-2/3 percent overload capability

Class 320: 50-amp meter with 640 percent overload capability

There are some exceptions to the rule. Refer to manufacturers instructions to be sure of the correct application for a particular meter.

FIGURE 9-5. Watthour Meter Geartrain

FIGURE 9-6. Meter Registers

FIGURE 9-7. Meter Nameplate

1.6.2 Register Multiplier (Kr): To obtain the correct number of kilowatthours, it may be necessary to multiply the value shown on the meter by a register multiplier or register constant Kr. The value of Kr, although shown on the meter nameplate, can be calculated as follows:

where:

Rr = register ratio found on front plate, back plate, or frame of register

Kh = watthour constant

TF = transformer factor = CT ratio x PT ratio

Gr = first gear reduction ratio usually 50 or 100 (obtain from manufacturer)

To determine total energy in kilowatt hours as counted by a transformer-rated meter, the secondary reading register would be multiplied by the ratio of the instrument transformers which is called the transformer factor. In a system using current transformers with a rated primary current of 20 amperes, total energy registered would equal:

If the system also contained a PT with a 7,200 to 120 ratio, the total energy registered would equal:

In this example, the numbers 4 (20/5) and 60 (7,200/120) are the ratios of CT and PT respectively. Their product, 240 (4 x 60), is the transformer factor for this meter. Whatever value is shown on the secondary register must be multiplied by the transformer ratio to obtain the correct number of kWh used in the primary circuit.

1.6.3 Voltage Rating: Meters are available for 120-, 240, or 480-volt service as required.

2. Permanent Kilowatthour Meter: A typical kilowatthour meter is shown in Figure 9-8. Watthour meters are commonly known by the type of electrical system for which they are designed , such as 3-wire single phase and 4-wire delta or wye meters. Basic characteristics of a typical kilowatthour meter are as follows:

- Configuration: Kilowatthour meters are available to measure energy consumption for all types of single and polyphase circuits. Two types of mountings are available: hard-wired A-type meter and socket and plug-in, S-type meter. In addition to standard registers, threevoptions are available: time-of-use register, demand register, andvpulse initiator.

- Register: Totalized kilowatthours (kWh) are displayed either in a four or five circular dial arrangement, or in digital form.

- Range: Self-contained meters are designed for services of up to 200 amperes and 600 volts. For higher voltages and currents, potential and current transformers are required. In many situations, for safety considerations, a potential transformer (PT) is preferred when voltages exceed 277 volts.

- Accuracy: Utility companies usually specify an accuracy of±2 percent and conformance to American National Standards Institute (ANSI) c-12 series standards.

- Installation: Power service must be interrupted to install an S- or A-type kilowatthour meter. If service cannot be interrupted, clamp-on split core transformers may be used. Core transformers are generally used as a temporary measure or for spot monitoring.

FIGURE 9-8. Kilowatthour Meter

2.1 S- and A-Type Kilowatthour Meters: The S- or A-type designation on a kilowatthour meter refers to the counting configuration. An S-type meter is a socket-mounted meter. A socket is hard wired into position and the meter is then plugged into the socket. The meter can then be removed any time without disconnecting wiring. The A-type meter is hard wired into position at the time of installation and requires complete disconnection of wiring for removal.

2.2 Transformer-Rated Kilowatthour Meters: If connected load exceeds 200 amperes and/or voltage of a circuit exceeds 600 volts , a transformer-rated kWh meter must be used in conjunction with instrument transformers. For safety reasons, transformers should be used when voltage exceeds 277 volts, even though meters without transformers are supplied for 480 and 600 volt service. Transformers reduce the voltage and line current to meter operating range. Both current and potential transformers are used for this purpose. Transformers can be either an integral part of the meter or a separate component. In using transformer-rated meters, it is important to know that two values of Kh may be shown on the meter nameplate. The first Kh which is a small numeric value is the Kh of the meter itself. The second Kh which may be shown as Kt, in which the subscript “t” stands for test, is the value used when the meter is being tested. There is another term which should be understood; this is the primary Kh abbreviated Pri Kh or PKh which is followed by a numerically large number. This value is the number of watthours of primary energy for one revolution of the disk and is equal to the Kh (of meter) x Transformer Factor. The transformer factor is equal to the product of CT and PT ratios. The CT ratio is always the rating of the CT divided by 5 and the PT ratio is the voltage of the primary circuit divided by 120.

2.3 Three-Phase Circuits: Polyphase watthour meters are applied to both delta ( D ) and wye (Y) circuits.

2.3.1 Three-Phase, Four-Wire Y Circuits: A three-phase, four-wire circuit is equivalent to three single-phase, two wire circuits having a common return circuit with potentials 120 degrees apart. It can, therefore, be metered with three two-wire meters or with a three-stator polyphase meter as shown in Figure 9-9. Because the voltages of the three phases are balanced, it is common practice to use a 2-1/2 stator self-contained watthour meter to meter this circuit. Connections for a self-contained watthour meter are shown in Figure 9-10.

2.3.2 Three-Phase, Three-Wire Circuits: Metering of a three-phase, three-wire circuit is accomplished in accordance with Blondel’s theorem by means of a two-stator meter having current coils connected in two lines and corresponding potential coils connected from these lines to the third line. The connection of a transformer-rated meter is shown in Figure 9-11.

FIGURE 9-9. Three-Stator Polyphase Self-Contained Watthour Meter in a Three-Phase, Four-Wire Y Circuit

Figure 9-10. Two-and-one-half Stator Meter in a Three-Phase, Four-Wire Y Circuit

FIGURE 9-11. Two-Stator Watthour Meter Connected to a Three-Phase, Three-Wire Circuit With Current Transformers

2.4 Kilowatthour Meter Reading: If a meter has a dial type register, it will either have four or five dials, as shown in Figure 9-8. The correct reading for a five-dial meter is 34310; the correct reading for a four-dial meter would be 4310. Every other dial moves counterclockwise. When the pointer is between two numbers, record the lower of the two numbers. When the pointer appears to be directly on a number, look at the dial to the right. If the pointer on the dial to the right has passed "O” toward “l,” then use the number the pointer appears to be on. If the pointer on the dial to the right has not passed “O,” use the previous, lower number on the dial being read. Subtract the previous reading from the present reading to determine kilowatthours used during the time interval. If the words “multiply by*’ followed by a number appear on the meter nameplate, the reading on the register must be multiplied by the number shown to obtain the correct value.

2.5 Meter Recording Developments: Recent developments in the field of meter recording promise increased accuracy and automatic processing of data. Meters currently available allow meter readings to be recorded even when the meter is inaccessible. Another development allows meter readers to record meter data on a hand-held device which resembles a pocket calculator. The hand-held device is preprogrammed to automatically evaluate the entered reading for tolerance from past readings. If beyond a programmed tolerance, it alerts the meter reader to a possible recording error. Data must either be corrected or “force” entered, in which case this fact will be noted. The exact time the meter was read is recorded to the second. All types of meters can be serviced. At the end of the day, the device is placed into a computer interface. The interface equipment automatically feeds all the information obtained that day into computer data files. The system also prepares reports with format and information selected by the utility manager. Systems similar to this help eliminate human error.

2.6 Field Testing: The accuracy of a watthour meter can be checked using a simple time test. The number of watthours for any period is the product of the number of disc rotations times the meter constant (kh). The speed of rotation of the disc indicates the use rate or watts being used. The kilowatt is a more reasonable quantity for consumption rate and the following formula can be used when timing a meter disc:

PTR = potential transformer ratio

CTR = current transformer ratio

K h = meter constant found on the face of the meter

REV = number of disc revolutions during observation period

s = period of observation in seconds

pKb = primary meter constant Kh x (PTR x CTR)

A stopwatch can be used to check meter accuracy using the formula given above. The calculated kW can be compared against a known load. If load remains constant, results are quite accurate. However, since accuracy depends upon a constant load which may be impossible to obtain in the field, it may be preferable to compare the watthour meter being checked against a watthour meter standard of known performance. Since both meters will be connected in the circuit, small variations in voltage, current, or power factor will not introduce errors as both meters are observing the same loads.

3 Demand Meter: A demand meter is a kilowatthour meter with an accessory clock motor and counter mechanism. The basic type of demand meter indicates a single maximum demand during a given time interval, using a sweep pointer. Behind the front plate there is a pointer-pusher mechanism that advances the pointer. After each demand interval, the pointer-pusher is reset to zero by the clock while the pointer remains at its last indicated high point. Therefore, the maximum demand during a single interval is registered regardless of the number of intervals spanned. The q aximum demand, in addition to total kWh consumed, is used for billing purposes.

3.1 Demand Register: A demand register is the register on a demand meter that indicates maximum load demand during a given interval of time, usually a 15- to 30-minute period.

4.1 Portability: To enable different points in a system to be measured, the PSR must be portable rather than fixed. Physical size and weight of portable meters varies and may require consideration.

4.2 Full-Scale Ranges: Because of the range of load demands encountered during a survey, a PSR should be able to measure both very small and very large loads. PSRs typically have measurement limits of approximately 600 volts and 1,000 amperes. Potential transformers extend voltage range and current transformers increase current capability.

4.3 Split Core Transformers: Although it is preferable to install metering devices before a load has been energized , many loads may be considered too critical for shutdown. In such instances , split core transformers may enable measurements to be made. With such devices, the circuit need not be interrupted for insertion of current meter elements.

4.4 Accuracy: A PSR must be accurate across the entire range of scales and parameters available. Poor accuracy reduces validity of calculations that are based upon PSR data.

4.5 Temperature and Humidity Limits: A PSR must be capable of providing accurate, reliable information in all climatic conditions encountered.

4.6 PSR Voltage and Frequency Requirements: Selectable voltage inputs for a PSR is advantageous. Metering in various locations may give rise to differing voltage requirements. Should voltage requirements exceed 600 volts, PT will normally provide the needed additional capability. Although only one frequency may be encountered at any particular facility, the PSR selected should be able to measure power at whatever frequency is present.

4.7 Availability and Compatibility: PSRs of various capabilities are available in the commercial marketplace. Prices and accessories vary considerably. When renting, leasing, or purchasing equipment, ensure that all components needed to undertake a complete survey are obtained. Additionally, ensure that survey equipment components are compatible with each other.

5. Tape Recorder Meters: A tape recorder meter is used often for periodic monitoring because it provides a graph that is easy to analyze. Tapes offer immediate data for use in comparing actual power demand with rate schedule provisions of the utility. These meters are portable and do not interrupt service when connected. The meter uses clamp-on type current transformers and may use battery power or 100 volts alternating current (VAC).

6. Time-of-Use Meter: Time-of-use meters have not changed for many years; improvements to them have been evolutionary rather than revolutionary. With availability of integrated circuit processors and electronic digital memories, tasks performed by these meters that were originally difficult or impossible, are now easier. This meter is based on a standard watthour meter structure with pulse output to an integral microprocessor-based register. With a precise internal clock it can be programmed to handle any time-dependent provisions in a rate schedule, such as time-of-day and time-of-year rate changes. The reduction of meter data can provide the following types of information:

- Total kWh

- Onpeak kWh

- Mid-peak kWh

- Offpeak kWh

- Onpeak kW demand

- Mid-peak kW demand

- Offpeak kW demand

7.1 Power-Factor-Meter: A power-factor meter indicates either a single or three-phase value leading or lagging. It requires both potential and current connections much the same as a wattmeter. Most power-factor meters are single-phase devices and are not accurate on either imbalance voltage or current on a three-phase system. Some electronic meters respond to zero crossings and, in the presence of distortion, are not accurate.

7.2 Negative Sequence Meter: A negative sequence meter indicates the presence and magnitude of negative sequence voltage or current, usually associated with system imbalance, fault conditions, or both.

Thank you for sharing this helpful article we hope listen you more ahead and I want to share information about weighing industryeleweigh

ReplyDeleteHi, i really needineed help,isais there anyone who can help me about this kV2c FM45s GE electric meter?

ReplyDelete