previous Modeling of a Truss

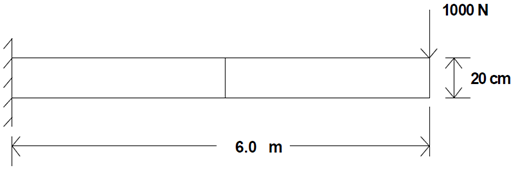

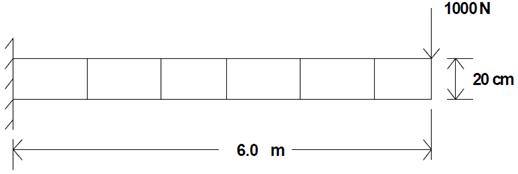

b) Rectangular 6 Element Mesh:

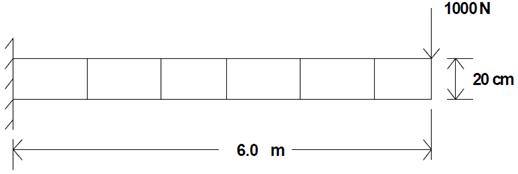

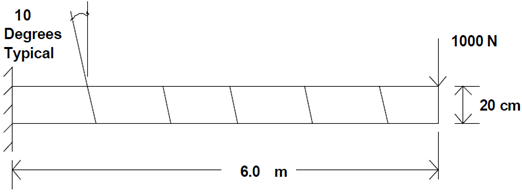

c) 10 Degree Parallelogram Mesh:

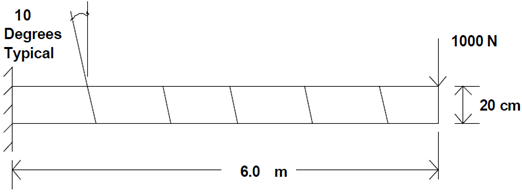

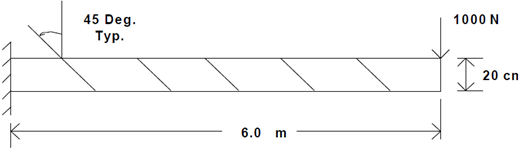

d) 45 Degree Parallelogram Mesh:

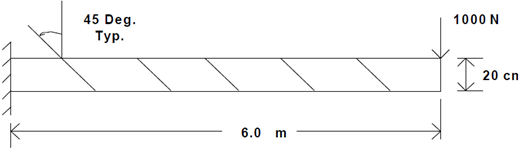

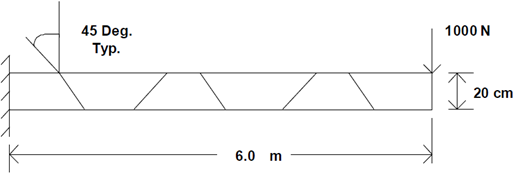

e) 45 Degree Trapezoid Mesh:

With : [B] = the strain - displacement matrix such that [B]{u} = {ε}

where: {u} is the dof vector and {ε} is the strain vector [E] = the constitutive matrix such that [E]{ε} = {σ}

where {σ} is the stress vector and V = volume.

and the rules for the shape functions are :

1) Ni must be =1 at node "i"

2) Ni must be =0 at any node not = "i"

Therefore,

the commas denote partial differentiation.

Assume that the element has constant thickness = t implies

Preliminaries for using PATRAN include:

a) Log on to the computer

b) Click START (lower left corner of the Windows Desktop), go to Programs, Select MSC (common), Select MSC Patran9.0.

TM = Top Menu. This refers to the horizontal menu options residing at the top of the screen after PATRAN has been initiated.

RM = Right Menu. This refers to the menus that pop up after an option has been chosen from the top menu. These menus reside on the far right side of the PATRAN desktop.

SM = Subordinate Menu. This referees to the menus that pop up from options selected in the right menu.

1. Our first step is to create a new database:

From the TM choose File In the resulting pull down menu choose New

A SM called New Database pops up

Turn on (checked) Modify Preferences

Under File Name enter beam.db

Click OK

2. Next set the analysis preference: A New Model Preferences window will appear as a RM

Under Tolerance choose Based on Model

Set Model Dimension to 6.0

Under Analysis Code choose MSC/NASTRAN

Choose Analysis Type = Structural

click OK

3. The geometry of the beam will be determined next:

From the TM choose Geometry A RM called Geometry will result

Set Action = Create Object = Point Method = XYZ Set the Point ID list to 1

Set Reference Coordinate Frame to Coord 0

Turn off the Auto Execute button

Enter the following into the Point Coordinates list:

[0,0,0] (note that PATRAN will accept either commas or blanks as separators between coordinates)

Click Apply

A point will appear in the main viewport at coordinates [0,0,0]

Method = XYZ Set the Point ID list to 3

Set Reference Coordinate Frame to Coord 0

Turn off the Auto Execute button

Enter the following into the Point Coordinates list:

[0,0.2,0] (note that PATRAN will accept either commas or blanks as separators between coordinates)

Click Apply A point will appear in the main viewport at coordinates [0,0.2,0]

Back at the top of the RM called Geometry

Set Action = Create

Object = Point

Method = XYZ

Set the Point ID list to 4

Set Reference Coordinate Frame to Coord 0

Turn off the Auto Execute button

Enter the following into the Point Coordinates list:

[6,0.2,0]

(note that PATRAN will accept either commas or blanks as separators between coordinates)

Click Apply A point will appear in the main viewport at coordinates [6,0.2,0]

Back at the top of the RM called Geometry Set Action = Create

Object = Curve

Method = Point

Set the Curve ID list to 1

Turn Auto execute off

Set Starting Point List = Point 1

Set Ending Point List = Point 2

Click Apply

Back at the top of the RM called Geometry

Set Action = Create Object = Curve

Method = Point

Set the Curve ID list to 2

Turn Auto execute off

Set Starting Point List = Point 3 Set Ending Point List = Point 4 Click Apply

Back at the top of the RM called Geometry Set Action = Create

Object = Surface

Method = Curve

Set the Surface ID list to 1

Set Patran 2 Convention off

Option = 2 Curve

Set Manifold off (not checked)

Set Starting Curve List = Curve 1 Set Ending Curve List = Curve 2

Click Apply

(Continuing on in the Load/BC's RM)

change Action = Create

Object = Force

Type = Nodal

Change the New Set Name to r_point

Click Input Data...

a SM appears

Enter the force vector <0 , -1000 , 0>

leave the moments < > (i.e. blank)

Click OK

(Continuing on in the Load/BC's RM)

Click Select Application Region

a small Patran select menu appears to the left edge of the RM

Click in this Patran select menu on the point icon

In the main viewport, click on the point 4 (top right corner of the beam)

A SM called Selection Choices menu appears.

Choose the Point 4 option, not the Curve or Surface option)

(Point 4 will be added to the Select Geometric Entities list)

Click Add (Point 4 will be added to the Application Region list)

Click OK

(Load/BC's menu now reappears)

Click Apply

(A vector with the 1000 unit downward load should appear on point 4 in the main viewport)

Set Action = Create

Object = Isotropic

Method = Manual Input

Click Material Name box

Input the name to be beam_matl Click Input Properties box

SM called Input Options appears

Input Elastic Modulus =200.0E9 Input Poisson = 0.0

Click OK

Back in the Materials RM

Click Apply

8. The properties for each element are assigned next:

On the TM select Properties a RM will appear called Element Properties Set Action = Create

Dimension = 2d

Type = Shell

Click Property Set Name box

Enter beam_prop Click Input Properties

a SM appears called Input Properties

Click in the Material Name box

Click on the word "beam_matl" in the Material Property Sets box at the bottom of the SM

( the words m:beam_matl will appear in the Material Name box at the top of the SM)

Click in the Thickness box

Enter 0.1

Click OK (Back in the Element Properties RM)

Click Select Members box

a Patran Select menu will appear on the left edge of the RM

Click on the icon which contains the surface or face icon

Click Add

(The words Surface 1 appears in the Application Region box)

Click Apply in the Element Properties menu

(beam_prop will be added to the Existing Property Sets box)

9. The analysis is to be done is specified next: On the TM select Analysis

a RM will appear called Analysis Set Action = Analyze

Object = Entire Model Method = Full Run

Click Translation Parameters

In the SM that appears, set Data Output = Op2 and Print

Click OK

Back in the RM Analysis Set Solution Type = Linear Static (button down)

Click OK

Click Apply

(The analysis will take a few seconds to run. A SM indicating that MSC/Nastran is working may appear)

On the TM select File From the pull down menu select Quit

next MODELING A FRAME STRUCTURE (WEIGHT BENCH) USING BEAM ELEMENTS

MSC/PATRAN TUTORIAL # 3

MODELING A CANTILEVERED BEAM WITH END LOAD USING 4 NODE SHELL ELEMENTS

MODELING A CANTILEVERED BEAM WITH END LOAD USING 4 NODE SHELL ELEMENTS

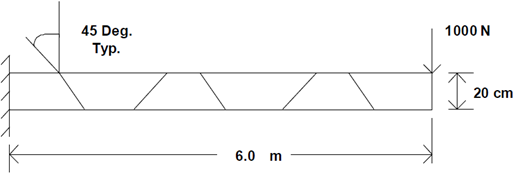

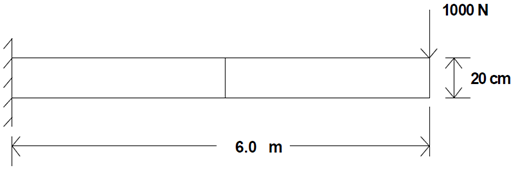

I. THE PHYSICAL PROBLEM

The beam below is cantilevered or "built in" on the left edge. This means that both the translations and the rotations are held to zero along this edge. A point or concentrated load of magnitude 1000 N (approximately 225 lb) in the negative Y direction is found at the tip of the beam. This problem is part of a standard set of test cases for finite elements published in a paper by MacNeal and Harder (MacNeal founded the company that makes the FEA code MSC/NASTRAN and MSC/PATRAN). The set of problems is called "The MacNeal - Harder Test Cases". The material properties for the beam are E= 200 x 109 Pascals (typical for steel) and ν = 0.0 (as the analytic beam theory we use below does not take Poison’s ration effects into account). The beam has a solid rectangular cross section with thickness in the Z-direction t = 0.1 meters and height in the Y-direction h = 0.2 meters.

The beam below is cantilevered or "built in" on the left edge. This means that both the translations and the rotations are held to zero along this edge. A point or concentrated load of magnitude 1000 N (approximately 225 lb) in the negative Y direction is found at the tip of the beam. This problem is part of a standard set of test cases for finite elements published in a paper by MacNeal and Harder (MacNeal founded the company that makes the FEA code MSC/NASTRAN and MSC/PATRAN). The set of problems is called "The MacNeal - Harder Test Cases". The material properties for the beam are E= 200 x 109 Pascals (typical for steel) and ν = 0.0 (as the analytic beam theory we use below does not take Poison’s ration effects into account). The beam has a solid rectangular cross section with thickness in the Z-direction t = 0.1 meters and height in the Y-direction h = 0.2 meters.

II. THINKING ABOUT THE MECHANICS

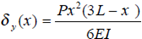

The analytic solution for stresses and displacements for this problem is readily available. Any Mechanics of Materials text will provide equations for the max stress (located at the built in edge and on either the top fiber for max tensile stress or the bottom fiber for max compressive stress) and the max displacement (located, of course, at the free tip where the load is applied). These equations are given below.

For the normal stress due to bending:

Some basic questions to consider before creating the computational model are:The analytic solution for stresses and displacements for this problem is readily available. Any Mechanics of Materials text will provide equations for the max stress (located at the built in edge and on either the top fiber for max tensile stress or the bottom fiber for max compressive stress) and the max displacement (located, of course, at the free tip where the load is applied). These equations are given below.

For the normal stress due to bending:

- Where will the stresses be tensile and where will they be compressive?

- What will be the magnitude and direction of the reaction forces/moments?

- Where will the stresses be zero?

- How do the displacements vary along the length (linear, quadratic etc.)?

- What will the local effect of the concentrated load be on the stresses?

- Is the model fully constrained from rigid body rotations and displacements?

Answering these questions qualitatively, along with the quantitative analytical solutions for the max stress and displacement will provide reinforcement that your computational model is correctly constructed.

III. GEOMETRIC AND FINITE ELEMENT MODEL As is the standard procedure for building MSC/Patran models, we will build the geometry first and then construct a finite element mesh on that geometry. The geometry will proceed from creation of points to lines to surfaces for this simple model. Next, we will use 4 node shell elements deforming in their membrane mode to model the beam. In this exercise, we will vary the exact number and configuration of these elements. This is discussed in detail in the next paragraph. Next, the material and element properties will be entered. We will constrain the 3 displacement and 3 rotational degrees of freedom on the left edge (for both nodes). This creates the cantilevered or built-in, end condition. Then we will, place a point load of magnitude 1000 on the top right node of the tip (or right-most) element. This load will be in the negative Y direction. Finally, the nodes must be equivalenced before the analysis is ready to run.

Below, we show 5 mesh configurations for the beam (labeled “a” through “e”). Comparison of results between mesh “a” and mesh “b” will indicate of how the number of elements affects the model’s ability to correctly model a beam problem. Increasing the number of elements in a mesh in order to increase the accuracy of the results is called “h” convergence. Meshes “b” – “e” all have 6 elements; but the elements have different orientations. Elements that have non-regular shapes are said to be distorted. Distorted elements can cause errors in the FEA results. This can be a significant problem in complex meshes as even the best automatic mesh generators often produce some distorted elements. The elements in MSC/Nastran have been specifically designed to minimize this unfortunate effect, but some sensitivity to element distortion may still remain. Different types of element distortion result in different levels of error. Evaluating results from the meshes “b” - “e” will provide you with some feel for how these elements perform when they are distorted.

Meshes for the “h” Convergence & Distortion Analysis

a) Rectangular 2 Element Mesh:

b) Rectangular 6 Element Mesh:

c) 10 Degree Parallelogram Mesh:

d) 45 Degree Parallelogram Mesh:

e) 45 Degree Trapezoid Mesh:

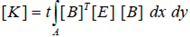

IV. FINITE ELEMENT THEORY

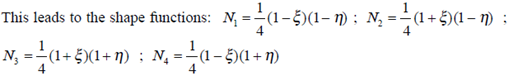

The exact details of the formulation of the 4 node shell elements in MSC/Nastran is rather complicated. However, the basic formulation of an isoparametric 4 node membrane element is not extremely difficult and will provide us with sufficient background information to begin to understand the “h” convergence and distortion sensitivity studies. This basic form is constructed as follows:

Isoparametric Formulation of a 2-D Membrane Element [K] Matrix Assume the element has the configuration shown below:The exact details of the formulation of the 4 node shell elements in MSC/Nastran is rather complicated. However, the basic formulation of an isoparametric 4 node membrane element is not extremely difficult and will provide us with sufficient background information to begin to understand the “h” convergence and distortion sensitivity studies. This basic form is constructed as follows:

The physical and natural coordinate locations of the 4 nodes are:

Our goal is to find the element stiffness matrix

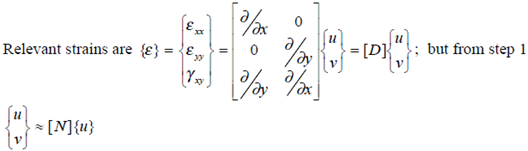

ASSUME: 2 displacement degrees of freedom (dof) per node With : [B] = the strain - displacement matrix such that [B]{u} = {ε}

where: {u} is the dof vector and {ε} is the strain vector [E] = the constitutive matrix such that [E]{ε} = {σ}

where {σ} is the stress vector and V = volume.

and the rules for the shape functions are :

1) Ni must be =1 at node "i"

2) Ni must be =0 at any node not = "i"

Step 2: Find the [B] matrix:

So {ε} » [D][N]{u} = [B]{u} with [B] = [D][N] Therefore,

the commas denote partial differentiation.

Step 3: Use the Jacobian to find derivatives:

i.e. the isoparametric assumption is that geometry can be interpolated using the same interpolation functions as the displacements.

This allows us to find the entries in [B]

Step 4: Perform the numerical integration: Assume that the element has constant thickness = t implies

Which, according to the rules of calculus can be written:

where |J| is the determinant of the Jacobian matrix.

Gaussian numerical integration is then used to find the final numbers for the element stiffness.

Where ngj and ngi are the number of gaussian integration points in the “j” and “i” directions respectively and wj and wi are the associated gaussian weighting factors.

Understanding the “h” Convergence Experiment:

From step 1 above we gain insight into the “h” convergence study. Remember that the that the analytic formula for the displacements as a function X (distance from built-in edge) is:

where P is the load, L is the length, E is the Elastic Modulus and I is the bending moment in inertia. This equation shows that the displacement is a cubic function of the distance from the cantilever. As the bi-linear (linear in both x and h ) shape functions are used to interpolate the displacements for this 4 node element, the elements are attempting to capture a cubic behavior by using a series of linear approximations. The number of linear approximations is equal to the number of elements we use (the actual situation when using MSC/Nastran’s 4 node shell element is a little better than this due to the innovative element formulation, but this is a good way to conceptually grasp the idea of “h” convergence). This is the reason why 2 elements give a higher error than do 6 elements.

Understanding the Distortion Sensitivity Experiment:

When an element is rectangular, its Jacobian matrix (used in steps 3 and 4 above) is numerically exact. However, if the element becomes distorted, the bi-linear shape functions used to form [J] can no longer exactly capture the geometry and the Jacobian is no longer numerically exact. This introduces error into steps 3 and 4 above. The exact form of the element’s distortion determines the amount of error which is introduced. As mentioned previously, the elements in MSC/Nastran are intricately designed to remove as much of this distortion based error as possible. If the simple standard isoparametric formulation shown above is used, the trapaziodal elements (mesh “e” above) would actually “lock” (become very stiff) and the errors in the displacements would be huge (over 90%). For this reason, it is critical that sophisticated, well-tested finite element codes be used for any critical analysis. Even then, it is wise to inspect meshes for regions where elements are highly distorted and attempt to create a less distorted mesh in that area.

V. STEP BY STEP INSTRUCTIONS FOR MODELING THE CANTILEVERED BEAM USING MSC/PATRANWhen an element is rectangular, its Jacobian matrix (used in steps 3 and 4 above) is numerically exact. However, if the element becomes distorted, the bi-linear shape functions used to form [J] can no longer exactly capture the geometry and the Jacobian is no longer numerically exact. This introduces error into steps 3 and 4 above. The exact form of the element’s distortion determines the amount of error which is introduced. As mentioned previously, the elements in MSC/Nastran are intricately designed to remove as much of this distortion based error as possible. If the simple standard isoparametric formulation shown above is used, the trapaziodal elements (mesh “e” above) would actually “lock” (become very stiff) and the errors in the displacements would be huge (over 90%). For this reason, it is critical that sophisticated, well-tested finite element codes be used for any critical analysis. Even then, it is wise to inspect meshes for regions where elements are highly distorted and attempt to create a less distorted mesh in that area.

Preliminaries for using PATRAN include:

a) Log on to the computer

b) Click START (lower left corner of the Windows Desktop), go to Programs, Select MSC (common), Select MSC Patran9.0.

The instructions below give details for modeling the beam problem discussed above. Specifically, the 6 rectangular elements (mesh “b” above) is constructed. If one wishes to create any of the other meshes, the mesh creation section must be adapted to fit that mesh.

In the instructions below, the following abbreviations and terms will be used: TM = Top Menu. This refers to the horizontal menu options residing at the top of the screen after PATRAN has been initiated.

RM = Right Menu. This refers to the menus that pop up after an option has been chosen from the top menu. These menus reside on the far right side of the PATRAN desktop.

SM = Subordinate Menu. This referees to the menus that pop up from options selected in the right menu.

Click = Unless otherwise stated, this indicates a click with the left mouse button.

Boldface will indicate text that occurs in the PATRAN menus.

Italics text will indicate text that you must enter into text boxes in the PATRAN menus or text that you choose in a menu scroll box.1. Our first step is to create a new database:

From the TM choose File In the resulting pull down menu choose New

A SM called New Database pops up

Turn on (checked) Modify Preferences

Under File Name enter beam.db

Click OK

2. Next set the analysis preference: A New Model Preferences window will appear as a RM

Under Tolerance choose Based on Model

Set Model Dimension to 6.0

Under Analysis Code choose MSC/NASTRAN

Choose Analysis Type = Structural

click OK

3. The geometry of the beam will be determined next:

From the TM choose Geometry A RM called Geometry will result

Set Action = Create Object = Point Method = XYZ Set the Point ID list to 1

Set Reference Coordinate Frame to Coord 0

Turn off the Auto Execute button

Enter the following into the Point Coordinates list:

[0,0,0] (note that PATRAN will accept either commas or blanks as separators between coordinates)

Click Apply

A point will appear in the main viewport at coordinates [0,0,0]

Back at the top of the RM called Geometry

Set Action = Create

Object = Point

Method = XYZ

Set the Point ID list to 2

Set Reference Coordinate Frame to Coord 0

Turn off the Auto Execute button

Enter the following into the Point Coordinates list:

[6,0,0]

(note that PATRAN will accept either commas or blanks as separators between coordinates)

Click Apply

A point will appear in the main viewport at coordinates [6,0,0]

Back at the top of the RM called Geometry Set Action = Create Object = Point Set Action = Create

Object = Point

Method = XYZ

Set the Point ID list to 2

Set Reference Coordinate Frame to Coord 0

Turn off the Auto Execute button

Enter the following into the Point Coordinates list:

[6,0,0]

(note that PATRAN will accept either commas or blanks as separators between coordinates)

Click Apply

A point will appear in the main viewport at coordinates [6,0,0]

Method = XYZ Set the Point ID list to 3

Set Reference Coordinate Frame to Coord 0

Turn off the Auto Execute button

Enter the following into the Point Coordinates list:

[0,0.2,0] (note that PATRAN will accept either commas or blanks as separators between coordinates)

Click Apply A point will appear in the main viewport at coordinates [0,0.2,0]

Back at the top of the RM called Geometry

Set Action = Create

Object = Point

Method = XYZ

Set the Point ID list to 4

Set Reference Coordinate Frame to Coord 0

Turn off the Auto Execute button

Enter the following into the Point Coordinates list:

[6,0.2,0]

(note that PATRAN will accept either commas or blanks as separators between coordinates)

Click Apply A point will appear in the main viewport at coordinates [6,0.2,0]

Back at the top of the RM called Geometry Set Action = Create

Object = Curve

Method = Point

Set the Curve ID list to 1

Turn Auto execute off

Set Starting Point List = Point 1

Set Ending Point List = Point 2

Click Apply

Back at the top of the RM called Geometry

Set Action = Create Object = Curve

Method = Point

Set the Curve ID list to 2

Turn Auto execute off

Set Starting Point List = Point 3 Set Ending Point List = Point 4 Click Apply

Back at the top of the RM called Geometry Set Action = Create

Object = Surface

Method = Curve

Set the Surface ID list to 1

Set Patran 2 Convention off

Option = 2 Curve

Set Manifold off (not checked)

Set Starting Curve List = Curve 1 Set Ending Curve List = Curve 2

Click Apply

4. The boundary conditions are specified next: From the TM choose Load/BC's

A RM called Load/Boundary Conditions will appear

Set Action = Create Object = Displacement Type = Nodal Set Current Load Case = Default Enter New Set Name as l_cant ( The name can be whatever name you wish. The name l_cant is chosen as this is for the cantilever of the left most nodes)

Click Input Data... a SM called Input Data appears

Set Load/BC Scale factor =1

Set Translations to <0,0,0>

Set Rotations to <0,0,0>

Be sure Analysis Coordinate Frame is Coord0

Click OK

(back in the Load/Boundary Conditions RM)

Click Select Application Region

A SM called Select Application Region appears

Turn on the Geometry (button down)

Click in box under Select Geometric Entities

In the Patran Select Menu (just to the left of the RM)

Click on the curve icon (just under the point icon)

In the main view port, select the left most vertical edge of the beam.

A Selection Choices SM appears

Choose Surface 1.1 ( This will cause the words "Surface 1.1" to appear in the Select Geometric Entities box in the RM)

Click on Add just below this box

( This will remove the words "Surface 1.1 " from the Select Geometric Entities box and adds them to the Application Region box)

Click OK

(The Load / Boundary Condition RM appears again)

Click Apply

A RM called Load/Boundary Conditions will appear

Set Action = Create Object = Displacement Type = Nodal Set Current Load Case = Default Enter New Set Name as l_cant ( The name can be whatever name you wish. The name l_cant is chosen as this is for the cantilever of the left most nodes)

Click Input Data... a SM called Input Data appears

Set Load/BC Scale factor =1

Set Translations to <0,0,0>

Set Rotations to <0,0,0>

Be sure Analysis Coordinate Frame is Coord0

Click OK

(back in the Load/Boundary Conditions RM)

Click Select Application Region

A SM called Select Application Region appears

Turn on the Geometry (button down)

Click in box under Select Geometric Entities

In the Patran Select Menu (just to the left of the RM)

Click on the curve icon (just under the point icon)

In the main view port, select the left most vertical edge of the beam.

A Selection Choices SM appears

Choose Surface 1.1 ( This will cause the words "Surface 1.1" to appear in the Select Geometric Entities box in the RM)

Click on Add just below this box

( This will remove the words "Surface 1.1 " from the Select Geometric Entities box and adds them to the Application Region box)

Click OK

(The Load / Boundary Condition RM appears again)

Click Apply

(3 displacement constraint arrows and 3 rotation constraint arrows should now appear on each point in the main viewport window on the extreme left edge of the beam. Numbers 1,2,3,4,5,6 will appear with the arrows to show that all 6 of the dof are constrained there)

5. The loads are specified next: (Continuing on in the Load/BC's RM)

change Action = Create

Object = Force

Type = Nodal

Change the New Set Name to r_point

Click Input Data...

a SM appears

Enter the force vector <0 , -1000 , 0>

leave the moments < > (i.e. blank)

Click OK

(Continuing on in the Load/BC's RM)

Click Select Application Region

a small Patran select menu appears to the left edge of the RM

Click in this Patran select menu on the point icon

In the main viewport, click on the point 4 (top right corner of the beam)

A SM called Selection Choices menu appears.

Choose the Point 4 option, not the Curve or Surface option)

(Point 4 will be added to the Select Geometric Entities list)

Click Add (Point 4 will be added to the Application Region list)

Click OK

(Load/BC's menu now reappears)

Click Apply

(A vector with the 1000 unit downward load should appear on point 4 in the main viewport)

6. The finite element mesh is specified next: From the TM choose Elements A RM appears called Elements

Set Action = Create

Object = Mesh

Type = Surface

Set Node Id = 1

Set Element Id List = 1

Set Global Edge Length = 1.0 (This will create 6 elements. If you want to create only 2 elements (as is needed to answer question #1 below) then set the Global edge length to 3.0)

Set Element Topology = Quad4

Set Mesher = Isomesh

Click in the Surface List box

Click and drag to select the entire structure

The Words "Surface 1" should appear in the Surface List Click Apply

Six elements will appear on the structure.

Set Action = Create

Object = Mesh

Type = Surface

Set Node Id = 1

Set Element Id List = 1

Set Global Edge Length = 1.0 (This will create 6 elements. If you want to create only 2 elements (as is needed to answer question #1 below) then set the Global edge length to 3.0)

Set Element Topology = Quad4

Set Mesher = Isomesh

Click in the Surface List box

Click and drag to select the entire structure

The Words "Surface 1" should appear in the Surface List Click Apply

Six elements will appear on the structure.

Set Action = Equivalence Object = All

Type = Tolerance Cube

(The purpose here is to tie the nodes together that lie on top of one another)

Set the Equivalencing Tolerance to .003

Click Apply

(The command window at the bottom of the PATRAN desktop will tell you that 0 nodes were deleted. This step will become critical if, in more complicated models, you are attempting to join portions of a model which have been meshed separately.)

7. The materials are specified next: On the TM select Materials a RM will appear called Materials Type = Tolerance Cube

(The purpose here is to tie the nodes together that lie on top of one another)

Set the Equivalencing Tolerance to .003

Click Apply

(The command window at the bottom of the PATRAN desktop will tell you that 0 nodes were deleted. This step will become critical if, in more complicated models, you are attempting to join portions of a model which have been meshed separately.)

Set Action = Create

Object = Isotropic

Method = Manual Input

Click Material Name box

Input the name to be beam_matl Click Input Properties box

SM called Input Options appears

Input Elastic Modulus =200.0E9 Input Poisson = 0.0

Click OK

Back in the Materials RM

Click Apply

8. The properties for each element are assigned next:

On the TM select Properties a RM will appear called Element Properties Set Action = Create

Dimension = 2d

Type = Shell

Click Property Set Name box

Enter beam_prop Click Input Properties

a SM appears called Input Properties

Click in the Material Name box

Click on the word "beam_matl" in the Material Property Sets box at the bottom of the SM

( the words m:beam_matl will appear in the Material Name box at the top of the SM)

Click in the Thickness box

Enter 0.1

Click OK (Back in the Element Properties RM)

Click Select Members box

a Patran Select menu will appear on the left edge of the RM

Click on the icon which contains the surface or face icon

Move the cursor arrow to a point to the left and above the highest, leftmost point on the beam. Click and hold down the left mouse button. Drag the cursor (while holding down the mouse button) to a point to the right of and below the right-most bottom node. A "selection box" is formed while you drag. Release the button.

(The words Surface 1 will appear in the Select Members box) Click Add

(The words Surface 1 appears in the Application Region box)

Click Apply in the Element Properties menu

(beam_prop will be added to the Existing Property Sets box)

9. The analysis is to be done is specified next: On the TM select Analysis

a RM will appear called Analysis Set Action = Analyze

Object = Entire Model Method = Full Run

Click Translation Parameters

In the SM that appears, set Data Output = Op2 and Print

Click OK

Back in the RM Analysis Set Solution Type = Linear Static (button down)

Click OK

Click Apply

(The analysis will take a few seconds to run. A SM indicating that MSC/Nastran is working may appear)

10. A graphical representation of the deformation can be produced. A graphical representation of the deformation provides an easy way to help determine if you have constructed your model correctly.

On the TM select Analysis

Set Action = Read Output2

Object = Results Entities

Method = Translate

Click Select Results File

A SM appears called Select File

Click the file beam.op2 (You may need to look in your home or root directory to find the file. If this file does not exist, then you have made a mistake in constructing your model. Go to Explorer (right-click on Start and choose Explore) and find the file beam.log and beam.f06. Open these files by double clicking on them and search for the word “error” to determine what your mistake is).

beam.op2 then appears in the File Name box

Click OK (back in the Analysis menu)

Click Apply

On the TM select Analysis

Set Action = Read Output2

Object = Results Entities

Method = Translate

Click Select Results File

A SM appears called Select File

Click the file beam.op2 (You may need to look in your home or root directory to find the file. If this file does not exist, then you have made a mistake in constructing your model. Go to Explorer (right-click on Start and choose Explore) and find the file beam.log and beam.f06. Open these files by double clicking on them and search for the word “error” to determine what your mistake is).

beam.op2 then appears in the File Name box

Click OK (back in the Analysis menu)

Click Apply

On the TM select Results A RM will appear called Results Set Action = Create

Object = Quick Plot

In the Select Fringe Result box click Displacements, translational In the Apply Fringe Result box click Displacements, translational

Set Quantity = Y Component

Click Apply

(This will create the deformed plot)

Note that stresses can also be plotted from the Results menu by specifying them in the Select Fringe Result section.

11. Next you will end your MSC/PATRAN session by saving your database and exiting. On the TM select File From the pull down menu select SaveObject = Quick Plot

In the Select Fringe Result box click Displacements, translational In the Apply Fringe Result box click Displacements, translational

Set Quantity = Y Component

Click Apply

(This will create the deformed plot)

Note that stresses can also be plotted from the Results menu by specifying them in the Select Fringe Result section.

On the TM select File From the pull down menu select Quit

next MODELING A FRAME STRUCTURE (WEIGHT BENCH) USING BEAM ELEMENTS

![Isoparametric Formulation of a 2-D Membrane Element [K] Matrix Isoparametric Formulation of a 2-D Membrane Element [K] Matrix](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhfHWjPLK33zQWkReUF_InKZtoubWLO8cyMK18UjtSdmzvfjVC3C3Xe89Mgvf-OGcLGjvcx7OQwBgLM0J-0yDVz9-Di1A_Li-pV5oLbShhseKwTCTQPaa3rduHSTnRSdClEstBpW3BswM8J/?imgmax=800)

0 comments:

Post a Comment

Please wait for approval of your comment .......