PRESENTATION ON Design and implementation of Digital Blood Pressure Meter

INTRODUCTION:

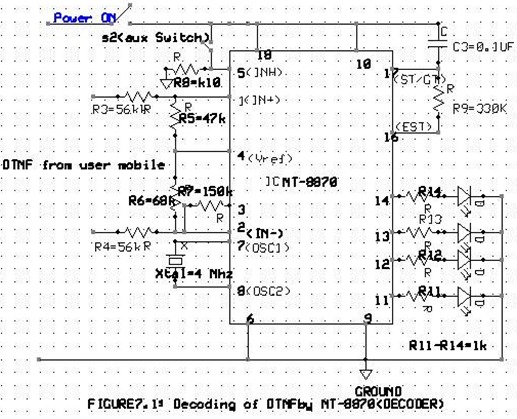

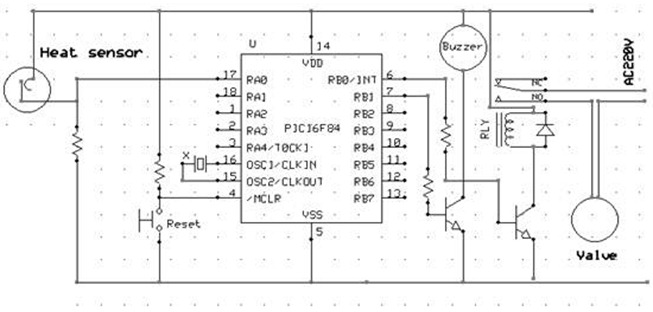

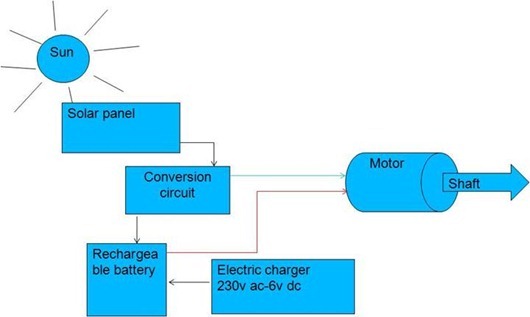

This application note describes a Digital Blood Pressure Meter concept which uses an integrated pressure sensor, analog signal-conditioning circuitry and microcontroller hardware/software and a liquid crystal display. The sensing system reads the cuff pressure (CP) and extracts the pulses for analysis and determination of systolic and diastolic pressure. This design uses a 50 kPa integrated pressure sensor (Freescale Semiconductor, Inc .P/N: MPXV5050GP) yielding a pressure range of 0 mm Hg to 300 mm Hg.

OBJECTIVE: We have worked to achieve the following goal:- To minimize the cost.

- To maintain the better performance.

- Easy measuring system.

- Display with digital unit.

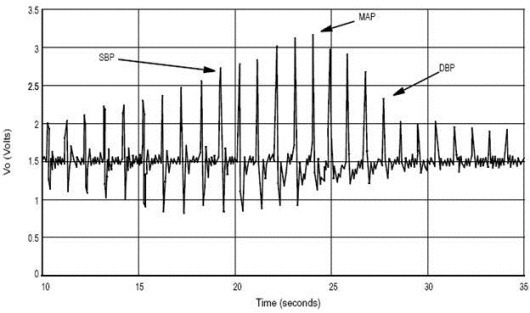

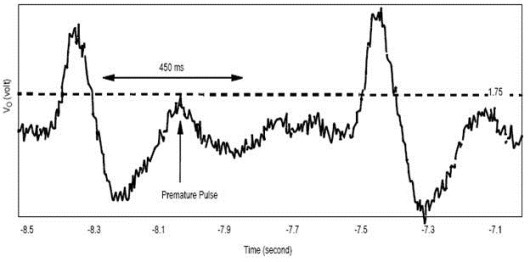

The cuff pressure is sensed by integrated pressure X-ducer. The output of the sensor is split into two paths for two different purposes. One is used as the cuff Since MPXV5050GP is signal-conditioned by its internal op-amp, pressure while the other is further processed by a circuit. The cuff pressure can be directly interfaced with an analog-to-digital (A/D) converter for digitization. The other path will filter and amplify the raw CP signal to extract an amplified version of the CP oscillations, which are caused by the expansion of the subject’s arm each time pressure in the arm increases during cardiac systole. The output of the sensor consists of two signals; the oscillation signal (≈ 1 Hz) riding on the CP signal ( ≤ 0.04 Hz). Hence, a 2-pole high pass filter is designed to block the CP signal before the amplification of the oscillation signal. If the CP signal is not properly attenuated, the baseline of the oscillation will not be constant and the amplitude of each oscillation will not have the same reference for comparison.

CP Signal at the output of the pressure sensor

Extracted Oscillation Signal at the Output of amplifier

Zoom-in View of a Pulse

Output versus Pressure

Comparison between our blood Pressure meter and Omron digital blood pressure meter

Cost Analysis

| Parts name | Quantity | Price(TK) |

| R0,R1,R2,R3,R4,R5,R6,R7,R8,R9,R10 | 10 | 30 |

| C1,C2,C3,C4,C5,C6,C7,C8 | 8 | 60 |

| LED | 1 | 1 |

| BUZZER | 1 | 30 |

| Crystal Oscillator | 1 | 10 |

| MPXV5050GP | 1 | 1500 |

| LM324N | 1 | 20 |

| MC78L05ACP | 1 | 25 |

| MC34064 | 1 | 20 |

| ATmega16 | 1 | 180 |

| LCD Display | 1 | 250 |

| Wire | - | 10 |

| Cuff | 1 | 70 |

| Total | 2206 |

METHODOLOGY:

- Theoretical study and analysis of pressure sensor and microcontroller.

- Calibrate the sensor in corresponding of pressure.

- Programming the microcontroller.

- Showing the systolic and diastolic pressure in LCD display.

Our Digital Blood Pressure Meter can be further improved by-

-Software programming

-Pressure sensor

CONCLUSION: This circuit design concept may be used to evaluate pressure sensors used in the digital blood pressure meter. This basic circuit may be easily modified to provide suitable output signal level. The software may also be easily modified to provide better analysis of the SBP and DBP of a person and also to calculate the pulse rate.

REFERENCE: [1] Electronic Principles, by Albert Paul Malvino p.h.d,EE,6th edition,pp 855-898.

[2] www.lvr.com,The Microcontroller Ideal Book, by Jan Axelson,pp 1-10.

[3] www.atmel.com. ATmega 16,data sheet.

[4] IC Design project, by Stephen kamaichick, first edition.

[5] www.alldatasheet.com. MPXV5050GP,data sheet.

[6] www.alldatasheet.com. LM324N,data sheet.

[7] www.mickrobasic.com

[8] www.alldatasheet.com,16×2 Display,Datasheet.

[9] www.fastavr.com

Submitted by Md. Omor Faruk Sharker and Abdul Halim Khan

![clip_image010[4] clip_image010[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhEuX4YeknaUSQTIcWe5_TcAA1wNqizu82P-JOTO1nERfginPb0wHvW_D7w6gQOCkrC1mQI1HwZMvTltZGZNExyNQ76ZFb8qcCB315o4bNdbVOduCnMiv4ZjLCWhEeeghWdxG-_1rB1wCeP/?imgmax=800)