The improvement of starter will allow it to be utilized in a great variety of application, such as various starting procedure. The starter circuit that proposed in this project design will be able to give several types of 3-φ Induction Motor starting procedure. Technology has bought the world into our hand .No matter what we are doing touch of science and technology is down there. Most of all this technology is imported and a large number of person and noticeable amount of money are involved behind this.

Fig-1.1 Flow chart of the project methodology

The full plan of the project is shown below -

Level 04 Term 01

|

Level 04 Term 02

| ||||||||||

Cycle

|

1

to

3

|

4

|

5

|

6

|

7

to

8

|

9

to

10

|

11

to

13

|

1

to

5

|

6

to

8

|

9

to

10

|

11

to

13

|

Study & Selection

| |||||||||||

Literature Review

| |||||||||||

Design &

Construction

| |||||||||||

Instrument Collection

| |||||||||||

Implementation

| |||||||||||

Data Collection

| |||||||||||

Result

| |||||||||||

Report Writing

| |||||||||||

It is well understood that induction motors draw higher currents during their starting operations than is the case under full load running conditions. Since the early days of induction motor availability, starting methods other than Direct-on-Line have been used, and in some cases mandated by Utilities, to reduce the effect of these high starting currents on the electrical distribution network. What is generally not recognized is the existence of short duration inrush currents that greatly exceed these starting currents. Furthermore, the introduction of complex starting methods to reduce starting currents is often compromised by other unanticipated inrush currents introduced by the starting system itself, unless special precautions are taken. This paper examines the sources and consequences of these inrush currents on the distribution system, as well as on the motor protection components. Recommendations are given in regard to the selection of both over current and earth leakage protection of induction motors that consider not only the motor protection requirements, but also the limitations on the protection devices that may result from the abnormal circuit disturbances that could be introduced through the starter.

Induction Motor

As a general rule, conversion of electrical power in to mechanical power takes place in the rotating part of an electric motor. In D.C motors, electric power is conducted directly to the armature through brush and commutator. Hence in this sense, a D.C motor does not received electric power by conduction but by induction in exactly the same way as the secondary of a 2-winding transformer received its power from the primary .That is why such motors as known as induction motor. in fact ,an induction motor can be treated as a rotating transformer one in which primary winding is a stationary but the secondary is free to rotate of all the AC motor, the poly phase induction motor is the on which is extensively used for various kinds of industrial drives.

Construction

The induction motor essentially consists of two parts

- Stator

- Rotor

The stator is the outer body of the motor which houses the driven windings on an iron core. In a single speed three phase motor design, the standard stator has three windings, while a single phase motor typically has two windings.

The stator core is made up of a stack of round pre-punched laminations pressed into a frame which may be made of aluminum or cast iron. The laminations are basically round with a round hole inside through which the rotor is positioned. The inner surface of the stator is made up of a number of deep slots or grooves right around the stator. It is into these slots that the windings are positioned. The arrangement of the windings or coils within the stator determines the number of poles that the motor has. A standard bar magnet has two poles, generally known as North and South. Likewise, an electromagnet also has a North and a South pole. As the induction motor Stator is essentially like one or more electromagnets depending on the stator windings, it also has poles in multiples of two. i.e. 2 pole, 4 pole, 6 pole etc.

The winding configuration, slot configuration and lamination steel all have an effect on the performance of the motor. The voltage rating of the motor is determined by the number of turns on the stator and the power rating of the motor is determined by the losses which comprise copper loss and iron loss, and the ability of the motor to dissipate the heat generated by these losses.

The stator design determines the rated speed of the motor and most of the full load, full speed characteristics.

Rotor - Squirrel case rotor: Motors employing this type of rotor are known as squirrel case induction motor.

- Phase wound: Motors employing this type of rotor are variously known as phase wound motor or as slip ring motor.

Al most 90 percent of induction motor are squirrel case type, because this type of rotor has the simplest and most rugged construction imaginable and is almost indestructible. The rotor consist of a cylindrical laminated core with parallel slots for carrying for rotor conductors which ,it should be noted clearly ,are not wires but consist of heavy bars of copper , aluminum or alloys. One bar is place in each slots ,rather the bars are inserted from the end when semi closed slots are used .the rotor bar are brazed or electrically welded or bolted to two heavy and stout short circuiting end rings. Thus given us, what is so picturesquely called a squirrel case construction.

It should be noted that the rotor bars are permanently short circuited on themselves; hence it is not possible to add any external resistance in series with the rotor circuit for starting purposes. The rotor slots are usually not quite parallel to the shaft but are purposely given a slight skew.

This is useful in two ways:- It helps to make the rotor end quietly by reducing the magnetic hum and

- It helps in reducing the locking tendency of the rotor the tendency of the rotor teeth to remain under the stator teeth due to direct magnetic attraction between the two.

In small motors another method of construction is used it consists of placing the entire rotor core in a mould and casing all the bars and end rings in one piece .the metal commonly used is an aluminum alloy.

Another form of rotor consists of a solid cylinder of steel without any conductors or slots at all! The motor operation depends upon the production of eddy currents in the steel rotor.

Phase wound rotor

This type of rotor is provided with 3-phase, double layer, distributed winding consisting of coil as used in alternators. The rotor is wound for as many poles as the number of stator poles and is always wounds 3-phase even when the stator is wound two phase.

The three phase are started internally. The other three winding terminals are brought out and connected to three insulated slip rings mounted on the shaft with brushes resting on them. These three brushes are further externally connected to a 3-phase star connected rheostat starting period for increasing the starting torque/current characteristics. When running under normal condition, the slip rings are automatically short circuited by means of a metal collar, which is pushed along the shaft and connects the entire ring together. Next, the brushes are automatically lifted from the slip rings to reduce the frictional losses and the wear and tear. Hence it is seen that under normal running conditions, the wound rotor is short circuited on itself just like the squirrel case rotor.

Methods of Motor Starting

In general, there are five basic methods of starting induction motors. These include-

- Direct - on - Line ( DOL ) starting

- Star - Delta or WYE - Delta starting

- Forward and reverse starting

- Autotransformer starting

- Reactor or Resistor starting

- Soft starting

Except for DOL starting, the prime objective of these alternative starting methods is to reduce the supply voltage to the motor, with the express purpose of reducing the inrush currents that occur during the starting operation. Reducing the supply voltage is an extremely effective way of reducing inrush currents, since the starting currents are directly proportional to the supply voltage. Unfortunately, as a consequence, the starting torque is reduced by the square of the supply voltage, so that this limitation needs serious consideration when choosing a method of starting induction motors.

Direct on line starting

The simplest form of motor starter for the induction motor is the Direct on Line starter .The DOL starter comprises a switch and an overload protection relay.

The switch may be a manually operated load break switch or circuit breaker, but more commonly it would be an electromagnetic contactor which can be opened by the thermal overload relay under fault conditions. Typically, the contactor will be controlled by separate start and stop buttons, and an auxiliary contact on the contactor is used, across the start button, as a hold in contact, i.e. the contactor is electrically latched closed while the motor is operating.

To start, the contactor is closed, applying full line voltage to the motor windings. The motor will draw a very high inrush current for a very short time, to establish the magnetic field in the iron, and then the current will be limited to the Locked Rotor Current of the motor. The motor will develop Locked Rotor Torque and begin to accelerate towards full speed.

As the motor accelerates, the current will begin to drop, but will not drop significantly until the motor is at a high speed, typically about 85% of synchronous speed.

The actual starting current curve is a function of the motor design, and the terminal voltage, and is totally independent of the motor load.

The motor load will affect the time taken for the motor to accelerate to full speed and therefore the duration of the high starting current, but not the magnitude of the starting current.

Direct-on-line or DOL starting has been used with success for many years, particularly with smaller squirrel-cage induction motors. It is unfortunate that many utilities still have restrictions in place that limit the size of motors that can be started direct on line. It is acknowledged that actual run-up starting currents are higher with DOL starting at 6 to 8 times motor full load current. This could present a problem on restricted or high impedance supplies, but becomes less of a problem as the power supply becomes stiffer. Less well understood is a higher inrush current, usually lasting for less than one cycle that occurs at the instant of DOL switching. The amplitude of these half cycle inrush currents is dependent mainly on the sub-transient reactance of the motor. With smaller motors, the increased cable impedance will have the effect of reducing the amplitude of the inrush current. When compared to the current surges that are experienced during open circuit transition switching, DOL inrush currents are at least 25% to 30% lower.

Motors are not damaged by these inrush currents, but any impact of mechanical shock to the motor load or gearbox needs to be considered. Since closed circuit transition starting is not the norm, it is becoming more and more obvious to users that the perceived advantages of open transition starting methods such as star-delta starting may not reach original expectations. It follows also that the additional cost and space requirements of such starting methods may not always be justified. An obvious consequence of this realization is that the DOL method of motor starting is becoming more widely used. Utilities that maintain unreasonable restrictions on DOL starting of induction motors may need to revisit and review their present restrictions.

Forward and Reverse starting

Forward operation of a motor is nothing but the direct on line Operation where motor runs in a particular direction where reverse operation means to change the direction of rotation of motor.

Reversing the connections to any two of the three motor terminals can reverse the direction of rotation of 3-phase induction motor.

Star Delta starting

Star/Delta starters are probably the most common reduced voltage starters in the 50Hz world (Known as Wye /Delta starters in the 60Hz world). They are used in an attempt to reduce the start current applied to the motor during start as a means of reducing the disturbances and interference on the electrical supply. In many, if not most, cases the star/delta starter does little to reduce problems; in fact it commonly exacerbates them.

Traditionally in many supply regions, there has been a requirement to fit a reduced voltage starter on all motors greater than 5HP (4KW). This regulation was introduced in order to reduce the start current, but unfortunately, a solution was specified rather than a result.

The Star/Delta (or Wye /Delta) starter is one of the lowest cost electromechanical reduced voltage starters that can be applied and this is why it has been so popular. The Star/Delta starter complied with the regulations, but did not achieve the desired results.

The Star/Delta starter is manufactured from three contactors, a timer and a thermal overload. The contactors are smaller than the single contactor used in a Direct on Line starter as they are controlling winding currents only. The currents through the winding are 1/√3 (58%) of the current in the line. There are two contactors that are close during run, often referred to as the main contactor and the delta contactor. These are AC3 rated at 58% of the current rating of the motor. The third contactor is the star contactor and that only carries star current while the motor is connected in star. The current in star is one third of the current in delta, so this contactor can be AC3 rated at ne third of the motor rating.

Fig-2.4 Star Delta starting procedure

Operation

In operation, the Main Contactor (KM3) and the Star Contactor (KM1) are closed initially, and then after a period of time, the star contactor is opened, and then the delta contactor (KM2) is closed. The control of the contactors is by the timer (K1T) built into the starter. The Star and Delta are electrically interlocked and preferably mechanically interlocked as well.

In effect, there are four states-

OFF state, All Contactors are open. Star state, the Main and the Star contactors are closed and the delta contactor is open. The motor is connected in star and will produce one third of DOL torque at one third of DOL current. Open state, The Main contactor is closed and the Delta and Star contactors are open. There is voltage on one end of the motor windings, but the other end is open so no current can flow. The motor has a spinning rotor and behaves like a generator. Delta state, The Main and the Delta contactors are closed. The Star contactor is open. The motor is connected to full line voltage and full power and torque are available.

This type of operation is called open transition switching because there is an open state between the star state and the delta state.

Starter Principle

When connected to the equivalent three phase power source, the voltage and current computation for each of star and delta connections are shown here. In comparison of the line currents to conclude, the line current of the star connection is one third of that of the delta connection.

Star Connection

Phase voltage, Vs = 3 phase voltage,

Phase Current, Is =

Line Current, I1 = phase current, Is1 =

Delta Connection

The comparison result of the line currents between the star and delta connections is shown here.

Design & Construction

This chapter consists of all fundamental block and their detail discussion. The required parts and technology are also enlisted here. This chapter will provide the necessary information about the parts that we need. Here all the connection diagrams are shown individually and also explain their working principle .One can reconstruct this project referring this chapter.

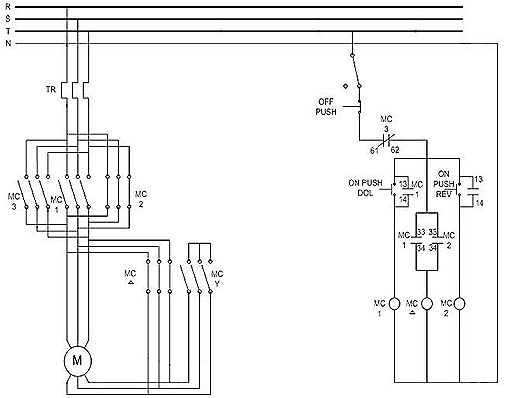

Block diagram representation of the circuit

Starting of a three phase induction motor is very similar. In starting of induction motor the main thing that is considered how the motor starts. The performance depends on the starting procedure. The block diagram of our circuit is as follows-

Fig-3.1 Block representation of the circuit

Description of the block diagram

From the block diagram we see that our design can be divided into two basic parts-

- Starter circuit

- Power circuit

Starter circuit

The starter circuit determines that how the motor will start. Below shows the starter circuit with the symbol-

Power circuit

Motor is feed from power supply with the help of power circuit. Power circuit operates according to respective starter circuit operation. Power circuit operation depends on the starter circuit. The main contacts shown in power circuit are operates according to the starter circuit operation. The power circuit is shown in below-

Circuit diagram for DOL starting

The circuit for Direct on line starting and its working principle is given below-

Working principle

In the circuit, when on push for DOL will press there is a close conducting path through coil of MC1. MC1 (13, 14) use for self hold contact. Magnetic contactor 1 will energize it changes its contact state. So the main contact of MC1 and also auxiliary contact MC1 (33, 34) will close for which coil for magnetic contactor Delta get energize. Now the main contact of MC∆ will close and the induction start running in Direct on Line.

Circuit diagram for Star-Delta starting

Star Delta starting has two state of operation-

- Star state operation

- Delta state operation

Star state operation

The circuit for star operation and its working principle is given below-

Working principle

From figure we see that when on push for Y-∆ press the magnetic contactor MC3 coil will energized and at the same time the timer coil and magnetic contactor coil MCY will energize. So the motor starts in star connection. The timer will change its state after some times that is defined by user.

Delta state operation

The circuit for Delta operation and its working principle is given below-

Working principle

When the timer changes its state, the timer auxiliary contact (1, 4) will open and the coil of MCY will de-energize and the main contact of MCY will disconnect and the coil of MC∆ will energize and the main contact of MC∆ will connect. The motor finally starts in delta state.

Circuit diagram for reverse starting

The circuit for reverse operation and its working principle is given below-

Working principle

In the circuit, when on push rev will press there is a close conducting path through coil of MC2. MC2 (13, 14) use for self hold contact. Magnetic contactor 2 will energize it changes its contact state. So the main contact of MC2 and also auxiliary contact MC2 (33, 34) will close for which coil for magnetic contactor Delta get energize. Now the main contact of MC∆ will close and the induction start running in reverse direction because MC2 main contacts changes the two terminals on stator side.

Components of design circuit

The various components we used to construct our design circuit are listed below-

Table 3.1 Parts list

| Parts name | Type / Rated value | Quantity |

| Magnetic contactor | 220V(coil voltage) | 5 |

| Timer | 220V(coil voltage) | 1 |

| Switch | Push button | 3 |

| Over current relay | 18 A | 1 |

| Induction motor | Squirrel-cage(2 pole) | 1 |

We choose the circuit and the various parts of the circuit. Below we discuss about the parts.

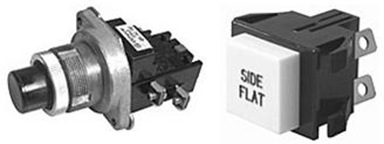

Magnetic Contactor

Engineers eventually made a breakthrough with the magnetic contactor.

A magnetic contactor is operated electromechanically without manual intervention. This means that the contactor can be operated remotely, without the need for putting a person in a potentially dangerous location. Magnetic contactors use a small control current to open and close the circuit.

A device that uses a small control current to energize or de-energize a load. Contactors can handle high amounts of current and are also combined with overload relays to create motor starters.

Fig-3.8 Typical connector connection diagram

How the Contactor Operates

How exactly does the contactor open and close? The E-Frame, when energized by the coil, becomes an electromagnet. The armature, a companion to the E-frame, is connected to a set of contacts. The armature is moveable but is held by a spring. When the coil is energized, the moveable contacts are pulled toward the stationary contacts because the armature is pulled toward the E-frame. Once the two sets of contacts meet, power can flow through the contactor to the load. When the coil is de-energized, the magnetic field is broken, and the spring forces the two sets of contacts apart. In Figure we step through the process again, using pictures to help you understand. Contactors are used when no overload protection is necessary, and at lower levels of electrical current. Applications include lighting circuits, heaters, and transformers.

In summary, contactors operate electromechanically and use a small control current to open and close the circuit. The electro mechanics do the work, not the human hand, as in a knife blade switch or a manual controller.

Over current relay

Types of overload relay that connects a heater with a motor. A thermal relay protects a motor by shutting it down if the relay detects excessive heat .The thermal relay line-up includes the phase failure protection type models (three-element relays). This array of protection characteristics allows you to choose the units suited to your motor protection needs.

- Switching from manual to automatic: Break the stopper off and then, slide the switchover plate to the right (to position "A") to immobilize the reset bar.

- Switching from automatic to manual: Slide the switchover plate to the left.

- Switching from manual to automatic: Flip the stopper on the end of the reset bar down and then , after pushing it all the way in, rotate it counterclockwise 90° (to position "A").

- Switching from automatic to manual: Rotate the reset bar 90° clockwise (to position "H") and the reset bar will pop out. (To position "H").

Benefits of Over current relay

- An operation indicator makes maintenance and inspection easy.

- 1 NO and 1 NC contact.

- Rated current can be set easily

- Trip-free reset bar.

- Convenient reset release (optional)

Our general purpose industrial relays are a low-cost way of adding control and isolation relays to any application .Electromechanical relays are available in cube and card styles for a diverse range of installation requirements. Cube relays are available with standard linear or octal base connection patterns. Solid state relays available include DIN-rail mount and panel-mount styles.

Fig-3.9 Timer Relay and Base.

Timers Timing Condition

Timer timing modes are discuss in below-

Condition 01: On-delay (Power Off)

- With power off turn the mode selector until PO is displayed.

- When power is on, applying the start signal turns the timed N.O. (normally open) contact on after the set time has elapsed.

- When using a power-on start, pins 2 and 6 (start signal) must be jumpered together

Condition 02: Flicker (FL)

- With power off, turn the mode selector until FL is displayed.

- When power is on, applying the start signal turns the timed contact on and off repeatedly at the set time intervals.

Condition 03: One-shot (OS)

- With power off, turn the mode selector until OS is displayed.

- When power is on, applying the start signal instantly turns the timed N.O. contact on and turns it off after the set time has elapsed.

- With power off, turn the mode selector until SF is displayed.

- When power is on, applying the start signal instantly turns the timed N.O. contact on. Removing the start signal turns the contact off after the set time has elapsed.

Push Button switch is nothing but a switch .Like normal switch it makes and breaks circuit connection but in different way .It can not hold its states .when it push it change its state after release the button it goes its previous stats. Suppose a switch is off when push it on after release it again off .To hold its own state it need a self hold contact.

Implementation & Measurement

Before using and certifying any equipment it needs to be tested. With this point of view after completing the full circuit design we first test the equipments in Machine lab of EEE department and observe the performance. Then build the circuit and also observe its performance. Various testing procedure and steps in making the circuit is described in the following section.

Testing of various equipments

In case of equipment test we have done following test-

- Magnetic contactor.

- Timer test.

Magnetic contactor test

Magnetic contactor is a device that uses a small control current to energize or de-energize a load. Contactors can handle high amounts of current and are also combined with overload relays to create motor starters. Magnetic contactor changes its state when its coil energizes it means normally close contact will open and normally open contacts will close. The contact condition is shown below-

Fig-4.1 (a) coil connection; (b) & (c) main contact condition before and after energize; (d) & (e) auxiliary contact condition before and after energize

From the Fig-4.1 we see that our magnetic contactor is ok and is ready to use.

Timer test

Timer is also an electromagnetic device like magnetic contactor but the difference is that it changes its state after certain defined period. The contact condition is shown below-

From the Fig-4.2 we see that the timer is ok and is ready to use.

Implementation of design circuit

The implementation of designed circuit has done in Machine Lab of EEE department of CUET. The implementation of the circuit needs different types of tools and techniques.

Required tools and materials

- Digital multimeter

- Hand Tachometer

- Wooden board

- Wooden box

- Pliers

- Screw drivers, Testers

- Cables

- Cable lucks

We drill the wooden board from our workshop and place all the magnetic contactors, timer and over current relay into the wooden board. Then lock them by nut and bolts. Then make all of our connections that given in circuit.

Making the cover box

We make our cover box using wood from the Workshop. The dimension of the box is given in Fig-4.3

Length 24 inchWidth 12 inch

Height 8 inch

Performance Analysis

Testing & Performance

The testing procedure and results are given below-

- First test the circuit for direct online stating. Then press the respective push button and see that the motor rotates successfully in clockwise direction. So we confirm that direct on line starting is successfully operated.

- Now for reverse operation, press the respective push button and see that the motor rotates successfully in counter clockwise direction. So confirm that reverse operation is successfully made by our circuit.

- Now for star-delta starting, push the respective push button and see that motor rotates slowly and also see that timer light is on. It means the timer counting its time that is defined by us. It indicates motor rotates in star connection. After the predefined time the motor rotates suddenly faster then before and the timer light is off. It indicates that the motor rotates in delta connection.

Data for starting current analysis

Starting current is an important characteristics for induction motor. The various starting procedure are introduced to minimize this starting current. The data for various starting current is given below-

Table-5.1 Typical starting current & running current data

| Types of operation | Starting current (A) | Running current (A) |

| Direct on line | 25 | 3 |

| Star operation | 13 | 1 |

| Delta operation | 10 | 3 |

| Reverse operation | 25 | 3 |

From the table that starting current is many times greater than the corresponding running current. This is harmful for motor. The starting current for direct on line is nearly twice then the star-delta starting. That’s why the high rating motors are not started at direct on line. For high rating motors always choose the star-delta starter to minimize the high starting current.

Result and Discussion

From the above analysis, we see that our circuit is useful for both high rating and low rating motors. Other hand it gives some additional features which are-

- Three individual operations will take place by one circuit.

- Operation is take place by pressing only four push button.

- No need to change any connection manually

- Compatible with other automation technique

- For compact design less magnetic contactor is required, so less cost

- Can be operated from remote location.

Nothing is perfect in this universe. The circuit performs well but still has some limitations. Limitations are summarized below-

- The starter circuit looks not so good because of using much wire.

- It can not be suitable for very high rating motors.

- It’s difficult to detect fault for using so many wire.

To solve any limitation we must need to know the cause of limitation then try to find the way to solve them. The cause and its way to solve are listed below-

- It need to design more compact circuit for reduce the connecting wire.

- The magnetic contactor rating is low. If high rating magnetic contactor is used it can be suitable for high rating motor starts.

- The more compact design can use to fault detection.

Though this designed circuit operates well in various starting mode it can be improved furthermore. The improvement which may be possible are listed below-

- In reverse starting, the motor rotates on Direct on line. It is possible on star delta operation at the time of reverse starting.

- It may interface with PLC.

nice Article thank you for posting

ReplyDeleteDOL Starter

Hi more information update here:https://www.techdoct.com/electrical/what-is-meant-by-power-circuit-and-its-material-to-make-a-starter/?preview=true

ReplyDeleteVery usefull informaton thanks for sharing this link share for more about How To Make A Electrical Starter and Power Circuit Click here

ReplyDeletethanks for information it was great information i also read some artical related to 3 phase motor control but u brief so well

ReplyDeleteHey, wow all the posts are very informative for the people who visit this site. Good work! We also have a Website.Please feel free to visit our site.Thank you for sharing.ElectricalPartAndSupplies

ReplyDeletePartsxp group has taken action to encourage sharing of surplus assets.It is given a Best price off every purchase.