Power Semiconductor Devices

Latest Post

Showing posts with label Instrumentation. Show all posts

Showing posts with label Instrumentation. Show all posts

INSTRUMENTATION IN METERING

previous ELECTRICAL ENERGY SURVEYS

Today’s versatile electronic instrumentation allows managers to manage their systems 24 hours a day without using meter readers. The old method of collecting data using meter readers, who periodically inspect and log readings for strategic meters, creates a reaction delay to situations that should be corrected immediately. For instance, in the event of a line break, modern instrumentation would report the leakage upon occurrence as opposed to later discovery by a meter reader. An instrument alerts the operator that an excessive flow is passing through the system and the manager can then take immediate action. The meter can record the time and magnitude of the leakage, actuate alarm systems, and provide a variety of signals to initiate corrective action. In addition to providing-information on occurring events, electronic instrumentation provides records for later viewing to analyze trends or significant changes or billing information.

1. Operating Principles: An electronic instrument records the amount of a media passing through a meter and converts it into an electrical signal to be displayed in meaningful units. Other equipment can be controlled based on this signal. Consumption registered on an electromechanical or electronic totalizer shows the amount of the media that has passed through the meter over a period of time. Quantity may be displayed in a variety of units, not necessarily those displayed on the meter register. A second common instrument display is the instantaneous rate through the meter.

1.1 Meter Output: The output is typically shown on an analog (a needle and scale instantaneous reading meter) or digital (a digital readout meter reporting in discrete scale increments) indicator. Output may also be fed to a variety of chart recorders for permanent records.

1.2 Meter Signals: Along with the basic outputs, modern processors are able to provide a variety of signals for use with computers and other process management equipment. Some examples of output signals are: 4-20 mA, 2-10 VDC, O-5 VDC, and 3-30 VDC pulse. If the data is to be entered into a computer system, an interfacing module can prepare the data signal for an RS-232C input application. These signals offer an infinite variety of system control functions and can provide data readouts to both local and remote locations. The receiving equipment is able to convert the data received from a simple slave device into a base for a complete management system.

2. Local Instrumentation: Figure 10-1 shows a meter sending an electronic signal to a local instrument that displays the instantaneous use rate on an analog indicator and the total use measured on a totalizer. The analog use rate indicator may be replaced with a digital indicator or a variety of recording devices, if desired.

2.1 Meter With Onsite Recorder: Figure 10-2 shows an equivalent package with a 31-day strip chart recorder that replaces the analog indicator of the system in Figure 10-1. This configuration is used when data is required at close intervals and no other data or functions are required of the metering operation. This arrangement would be useful to the onsite operator who requires an Immediate data record.

FIGURE 10-1. Meter With Onsite Monitoring

FIGURE 10-2. Meter With Onsite Recorder/Totalizer

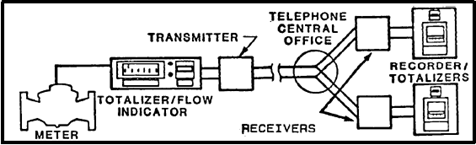

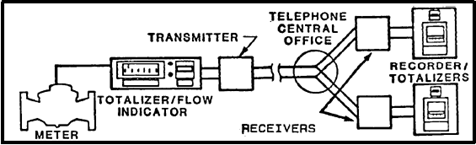

3. Remote Instrumentation: With the advent of inexpensive PCS, software, and new meter technologies, most utilities management functions can be automated within the foreseeable future. Meter data may be transmitted to remote locations by adding a transmitting option and the appropriate transmission equipment to the metering system. The transmission distance is limited by the equipment and the availability of a communications link between the meter site and the remote location. Figure 10-3 shows an expansion of figure 10-1 with the meter-generated data being displayed onsite and also being transmitted via the telephone system to a remote point that may be many miles from the meter site. If information is not required onsite, the onsite instrument can be replaced with a transmitting module as shown in Figure 10-4. Transmitted data can be analyzed automatically using specially adapted PC software, and reports such as the Utilities Cost Analysis Report (UCAR) and the Defense Energy Information System (DEIS) II Report can be generated and transmitted automatically. Because of the cumbersome nature of present systems of meter reading, recordkeeping, billing, and reporting, very little analysis is performed. Modernizing the way utilities are managed will save money, improve readiness, and provide better support to the fleet.

Remote monitoring technology will enable a utilities mangement system that will automatically record metered consumption data for major utilities at an activity and send data to a central PC. The PC will receive the data, and automatically generate utility bills for tenants. In addition, remote monitoring equipment installed at major steam, electric, compressed air, and chilled water generating plants will provide detailed information on equipment status and performance. This data, along with utility company cost and consumption data, operations and maintenance personnel cost data, material cost data, and other information, will be used to automatically generate various analyses of utilities costs and performance. These analyses will allow managers to make decisions that will result in optimized operations in the present and future.

3.1 Remote Interfacing Kilowatt Meters: There are two reasons for providing a kilowatthour meter with a pulse initiator. The pulse initiator allows for monitoring of the load center on a temporary basis or collecting remote data on a permanent basis. In either case, pulse initiators are manufactured with a variety of output signal parameters and care must be taken to ensure compatibility of components. For applications requiring a distance between the pulse device and data collection point of over 50 feet, the signal may require reinforcement. Increased voltage and the use of signal repeaters are two common methods used. Do not attempt any signal manipulation without first referring to the manufacturer’s instructions of all equipment involved.

3.2 Transmission to TWO Points: The need to have data transmitted to two remote points is frequently necessary in the wholesaling or custody transfer of the commodity. In these applications, both the supplier and the end user must have meter data readily available to them. Figure 10-5 depicts a means of accomplishing the task with one telemetry transmitter. Figure 10-6 shows a system with two data channels if the channels must be isolated.

3.3 Repeater Transmission: Repeater data transmission systems provide the user with a relatively inexpensive means of sending data to a remote point, as shown in Figure 10-7. Although repeaters accomplish the transfer of data from local to remote points at a cost of approximately 10 percent of what other transmission systems cost, they do have limitations. The primary consideration when a repeater is contemplated is its requirement for a dedicated wire pair. When using a repeater, no other signals may be on the wire pair. Repeaters also have finite distance limitations, usually expressed in ohms rather than distance, because the gauge of transmission lines varies. Typically, a repeater system is limited to a maximum transmission loop resistance of 4,000 ohms. Another means of data transmission is the use of a modem through existing telephone lines which is cost effective since the cost is only the price of a telephone call.

4. Computer Management: The system shown in Figure 10-8 usually requires telemetry of data from a number of meters in a system, to a central point where the data is converted into a computer compatible signal (RS-232C). In this system, the computer continuously monitors the data lines. It immediately warns the operator when a signal is not within programmed limits.

FIGURE 10-3. Onsite and Remote Monitoring

FIGURE 10-4. Metering System With Interface Module

FIGURE 10-5. Single Transmission Split in Communication Link

FIGURE 10-6. TWO Transmission Modules--Two Data Channels

FIGURE 10-7. Extended System Using a Repeater

FIGURE 10-8. Multi-Input System

FIGURE 10-9. Chart Recording System

On demand, the computer prints a complete analysis of the system and output totals to present. When strategically located meters are connected to a computerized system with critical parameters, the computer can instantaneously provide the information necessary to monitor, control or operate a system.

5. Demand Billing: As the cost of energy, materials, and labor increases, there is a need to limit the large, intermittent demands on systems and to encourage utilization during offpeak periods. To accomplish this task and identify systems not in conformity with policy, instrumentation is required.

5.1 Control Parameters: Control parameters depend on the characteristics of the system. Some systems are limited in peak capacity and must control maximum use. There may be other areas of concern that are unique to a particular system, such as a user who intermittently uses power at a rate that overloads the system, affecting many other users.

5.2 Recorder Types: Common instruments used in a demand billing system are a rate recorder such as the one illustrated in Figure 10-2, or a circular recorder, as shown in Figure 10-9. Circular recorders are not highly effective if data reduction is required and have been replaced with a data logger with reduction by microprocessor program. These devices record the use rate continuously. Peaks are easily detected over the period of recording. If a recorder is used, the preferred type is a linear tracking, multichannel recorder. One advantage of this system is that the chart becomes a permanent record in case of customer disagreement concerning subsequent billings.

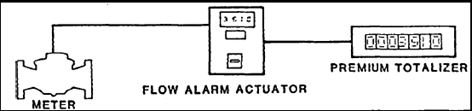

5.3 Alarm Actuator: A unique variation of chart recorders is shown in Figure 10-10. In this application the utility installs an instrument with a recorder onto user equipment. The agreement with the user is that severe penalties will be levied each time the use exceeds a predetermined rate. In an effort to avoid the penalty, a two-point alarm actuator is installed with an alarm programmed to respond at some warning point before the limit is reached, and then to initiate action if the limit is exceeded.

5.4 Alarm With Totalizer: Another variation of a use rate and penalty system is shown in Figure 10-11. This approach places a penalty (generally a unit price increase) on all consumption exceeding the limit. This is accomplished by employing an alarm actuator and using a totalizer to record the excessive usage.

SYSTEM COMPONENTS: 1 Meter Energy Usage. Although each medium requires a specific type of meter, all meters must have a signal-generating device to provide either onsite or remote data reading and recording capabilities. The meter must sample the media and transmit a representative signal to the system. Electric meters rely on the medium they monitor for energy to produce the monitoring signal. Turbine meters generate their own signal. Many meters rely on an outside source of electricity to produce a transmission signal.

FIGURE 10-10. Alarm Actuator System

2. Signal Generators: Electronic or electromechanical signal generators are available that produce analog and/or digital signals for transmitting data to data processing equipment (onsite meters or recorders) or to a more complex remote system.

2.1 Analog Output: The analog output of a signal generator is a continuous signal representing the quantitative information obtained by the meter.

2.2 Pulse Output: A pulse output is a discrete series of pulses produced by the signal generator representing quantitative information.

3. Power Supply: Power supplies are a required part of many systems to supply low voltage in direct current (VDC) and low current in milliamperes (mA) for excitation of the signal generator. The low voltage and current is processed by the signal generator, producing an analog and/or digital signal, for transmission to the monitoring system.

4. Pulse Rate Converter: The pulse rate converter (PRC) is designed to interface between the meter pulse generating unit and measuring equipment. The device accepts low-level input frequency signals, processes the signals, and provides output signals that are proportional to the use rate.

5. Pulse Compensator: Pulse compensators are self-contained electronic modules which compensate the output pulse train of a meter with respect to a secondary process variable such as temperature, pressure, or density.

6. Frequency-to-Current Converter: The frequency-to-current converter (FCC) converts the pulse output from a meter or other transmitter into a proportional 4-20 mA current loop signal.

FIGURE 10-11. Alarm Actuator and Totalizer System

7. Repeater: The repeater is used to extend the distance the remote equipment can be located from the meter. The repeater is located as close as practical to the meter. The repeater allows reduction of the electrical load on the meter generator electrical contacts, extending the life of the device. It also provides a strong signal to allow monitoring equipment at remote locations to be as much as several miles from the meter.

8. Accumulators: When it becomes necessary to place two or more meters in parallel to satisfy a system requirement, an accumulator collects and combines data from these meters and transmits a totalized signal to the remainder of the system.

ELECTRICAL ENERGY SURVEYS

previous METER INSTALLATION

DATA FROM DEMAND SURVEYS: Electric bills may provide only the peak demand for a month or the average of three or four highest peaks for a month, depending on how the particular utility company computes maximum billing demand. No indication is given of how this peak compares to the balance of the demand profile for the interval, nor what combinations of loads caused the peak. This information can only be acquired by monitoring key points in the internal electrical system.

1. System Information: Each electrical system is different, but system information for each follows a similar pyramid pattern, with overall system information available at the peak and an increase in detailed information available as the base is approached. Figures 9-15, 9-16, and 9-17 illustrate the process of demand surveying in three phases.

2. Survey Starting Point: The survey should begin at the utility service entrance. If a pulse initiator is in place, a demand analyzer can be connected without need for voltage or current connections. If a pulse initiator is not installed, additional connections will be required. Consult the user manual for the demand analyzer before making any connections.

2.1 Utility Service Entrance: A utility service entrance demand profile gives considerable information about the overall system. Comparing profiles obtained from system monitoring will provide answers to the following questions and will prove valuable in analyzing an electrical system.

- What is the peak facility load in kilowatts?

- What day of the week did it occur?

- Was the peak the same each day? If not, why?

- What is the after-hours load? Was it the same each day/night?

- Is there evidence of power wasted by starting equipment before hours or letting it run unnecessarily during lunch or after hours?

- HOW does the peak compare with the utility company’s demand charge for the previous month?

- Could a slight change in startup time save money?

- HOW long did it take the facility to reach full power load after starting time?

- Is there a tendency to anticipate quitting time?

- What is the maximum power factor of the load? What is the minimum?

- When did the minimum power factor occur? What caused it?

- How does the power factor compare with the one on which the previous power bill was based?

- What is the voltage drop between the main power bus and the various major consumers.

FIGURE 9-15. Demand Survey, Phase I

FIGURE 9-16. Demand Survey, Phase II

FIGURE 9-17. Demand Survey, Phase III

If the profile peaks radically at only a few points, then demand leveling could lead to a reduction in demand charges. An exception to this may exist because of peaks caused by individual pieces of equipment, or allied pieces, that must operate together. It may be preferable for the equipment use to be shifted to a reduced-demand charge period. If the demand profile is reasonably level, it may indicate that reduction of demand charges can only be obtained through planned reduction in total consumption.

3. Specific Load Profiles: The next step in a demand survey is to record electrical power consumption by substation, building, and department. This enables the facility engineer to associate some of the causes of the undesirable conditions with more specific load profiles. Some information obtained from recording instruments at the building level will provide answers to the following questions.

- Did the building equipment start on time in the morning and after lunch?

- What is the load at noon and night?

- How long did it take for the building and each department to reach full power load after startup?

- To what extent was quitting time anticipated at noon and in the evening? Were machines left running idle?

- What is the idle load in the building?

- Does the building have a peak load that corresponds to the total facility peak? What causes it? Could a change in scheduling reduce the power demand?

- Is there evidence of pyramiding loads which cause excessive or pulsating peaks?

- Does anything in the record offer explanations as to the waste of power?

- What proportion of the demand charge and energy consumption should be allocated to this building?

- What is the power factor?

4.1 Equipment Monitoring: If electrical power consumption is excessive, the equipment may be overloaded or faulty. If equipment is drawing more current than expected, it may indicate the need for a more efficient motor. Answers to such questions are especially informative in interpreting performance of automatically-operated equipment. The record shows when and how long each machine was operated and how long it was idle. It discloses waste if automatic equipment is not functioning properly. Monitoring individual equipment will answer the following questions;

- (a) What are maximum, minimum, and average loads for the equipment? Are they within specifications?

(b) If the motor is not the correct size, what is the horsepower of the motor that should replace it?

(c) Is there sufficient voltage at the motor terminals?

(d) How much does the unit contribute to peak load?

(e) Could the equipment schedule be rearranged to reduce peak load?

(f) Is load on a unit a contributor to any loss of productive effort shown by the department record?

(g) What is the idle load of this unit?

(h) Does the idle load show any marked increase since the last survey?

(i) Does the record show any characteristic which indicates a faulty condition in the motor or the associated equipment?

(j) How does the record compare with other records of similar equipment?

(k) Does the record show any data valuable in reducing energy consumption?

INTERNAL SURVEYS: Assuming that improvements seem possible, then further investigation must be carried out to determine what load makeups are causing the demand peaks and what can be done to shift load combinations to reduce these peaks.

1. Demand Survey Example: Each electrical system is different, but they all spread out like a pyramid, with total facility information available at the peak and more detailed information available as the base is approached. At whatever point a demand analysis is made, it must be carried out for a full cycle of operations so that normal permutations and combinations of loads are encountered. Depending on the facility, a full cycle may be a day, but more likely a week, and sometimes a complete month or billing period is required. Figure 9-18 shows a typical situation with three substations and three feeders per substation. The survey should begin at the utility service entrance.

1.1 Service Entrance: A utility service entrance demand profile gives considerable information about the overall plant. If it peaks radically at a few places then demand leveling could lead to a reduction in demand charges, unless the peaks are being caused by individual or allied pieces of equipment which must operate together. It may be profitable to shift these loads to a reduced demand charge offpeak period, if the rate schedule includes such time-dependent provisions. If the demand profile is reasonably level, it may indicate no need for load shifting.

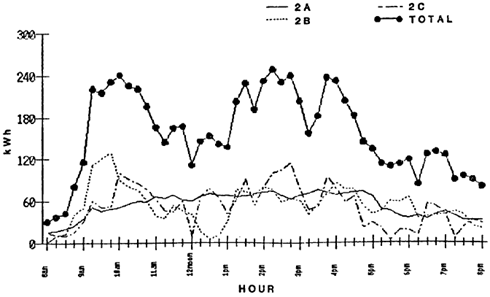

1.2 Substation and Feeders: In Figure 9-18, the demand of the three substations and the individual feeders supplied by the substations are monitored. Provided that the demand studies are carried out at comparable times in the plant operating cycle, and that successive operating cycles show reasonable consistency, the three substation demand profiles should be roughly equal to the overall plant profile. The sum of the individual feeder profiles should roughly equal the respective substation demand profile. Figure 9-19 shows this concept for substation No. 2 and feeders 2A, 2B, and 2C. These plots were obtained on four successive Wednesdays from data obtained by monitoring the three feeders and the substation output from 8:00 AM to 8:00 PM.

FIGURE 9-18. Three Substations With Three Feeders Per Substation

1.3 Profile Analysis: In Figure 9-19 the peak demands occur around 10:00 AM and during the period from 1:00 PM to 5:00 PM. After the morning buildup, feeders 2A and 2C show level demand, with the substation peaks being principally caused by erratic loading of feeder 2B. If the demand on feeder 2B is made up of many small loads, then a better time distribution of these loads would level demand on this feeder and consequently on substation No. 2. Other possibilities are to shift loads on feeders 2A and 2C away from the peaks of feeder 2B, or to transfer some of the peak loads on any of the feeders to second shift. If these steps are not possible, then the peaks from this substation could be mated to the valleys from other substations.

1.4 System Management: Developing a series of plots for an entire facility and designating the principle loads on the plots, gives a clear picture of the overall demand situation, building from the base of the pyramid to the peak. Such information is invaluable in developing procedural steps that reduce demand charges or developing an energy management system program.

2. Periodic Studies: It is important to remember that changing market forces and equipment requirements create needs to modify a system load makeup. Therefore, periodic studies should be carried out, at least at the utility service entrance, to make sure that gains from a previous energy audit are not outdated.

FIGURE 9-19. Demand Profiles

next INSTRUMENTATION IN METERINGMETER INSTALLATION

previous ELECTRICAL METERING COMPONENTS

General Information: Before starting any work, the person in charge should assemble the entire crew for a job briefing. The job briefing should include an outline of the following items:

- The work to be done.

- Each crew member’s part in the job.

- The hazards known or anticipated during the task.

- Safety precautions to enforce while working.

If during the course of the work, changes in the plan become necessary, members of the crew who are affected must be called together and the changes explained.

1.1 Prior to Installation: Before installation of any equipment, the person in charge should identify all the circuits present. Conductors should be identified in terms of circuit and voltage, both at the point where work is to be done and at all switching and grounding points involved. Prior to installation of metering equipment, the supervisor of the building, or area of the building receiving its electrical supply from the metering point, should be advised of the installation. Barricades or barriers should be installed to prevent unauthorized entry into the area near the meter installation.

1.2 Portable Meters: To collect reliable data while performing an electrical energy survey, the proper meter for the job must be obtained. The following list of equipment parameters should be considered:

- Maximum voltage rating.

- Maximum load current (in amperes).

- Accuracy.

- Number of simultaneous demand values to be recorded.

- Power factor ranges.

- Full-scale ranges.

- Temperature working limits.

- Input power requirements.

- Type of meter enclosure.

- Weight.

- Overload protection.

1.2.1 Connecting the Meter: The items listed below are supplemental to manufacturers’ instructions and are provided to assist in safer and more accurate meter operation.

- Make only one connection at a time. Work on only one conductor or point at a time.

- Check all selectable meter settings to confirm configurations for monitoring desired parameters.

- Check zero for all parameters.

- Observe polarity of all meter connections.

- Connect additional ground; use #12 copper wire.

- Reset all counters, integrators, and totalizers.

- Some meters require warmup time. Allow meter to acclimate to conditions at the test site.

- Replace all protective covers when setup is complete.

The following items, coupled with the recommended safety equipment (as shown in the safety summary), assist in successful completion of electrical power surveys using a PSR. The required quantities of items listed depend on the number of personnel performing electrical power surveys. Ample quantities of the following items should be kept in good condition and readily available.

- Barriers and warning signs.

- Live-line and switch tags.

- Padlocks and locks.

- One-line diagram of building.

- Insulated flashlight.

- Clamp-on voltammeter and ohmmeter.

- Approved three conductor extension cord with grounding plug.

- Electrical insulating tape.

- Light meter.

1.3 Permanent Meters: The more common types of permanent meters include the S-type mounted with a socket and the A-type which is hard wired in its permanent position. These meter types are designed for original installation in new buildings or as retrofit equipment when conditions warrant monitoring an in-place electrical service. In most cases , electrical service must be interrupted to install or remove a meter.

1.3.1 Socket-Connected S-Type Meters: To install the S-type meter, perform the following procedures:- Meter should be installed plumb and in a location that is free of heavy vibration.

- Make sure that meter socket is mounted securely in place and in a position that the rotor shaft will be vertical when meter is mounted.

- TO ground meter frame and surge protectors (if present), good contact between ground straps and socket rim must be ensured. To ensure good ground, scrape off any paint between straps and socket rim at points of contact before fastening them together.

- Make connections to socket terminals per manufacturer’s instructions. For connections of pulse initiators, consult manufacturer’s instructions for the particular type of device being operated.

- Plug meter into socket. Make sure meter terminal blades engage with socket jaws. To ensure connection of meter to its load circuit before line voltage is applied, always insert meter load (bottom) terminal blades into socket jaws first; when removing, withdraw them last.

- Push meter into place so that the base fits tightly against socket rim. If sealing rim is used, place it around adjoining meter cover and socket rim. Position rim so that clamp is at bottom.

- Seal or latch rim as required.

- For connections of pulse initiators, refer to manufacturer’s instructions for particular type of end device being operated by the pulse initiator.

1.3.2 Bottom-Connected A-Type Meters: These meters have mounting and terminal chamber dimensions that conform to industry standards. Therefore, mounts for bottom-connected A-type meters are interchangeable with all brands of A-type meters. To install an A-type meter, proceed as follows:

- Locate mounting holes in mounting base of meter.

- Obtain necessary type and size mounting screws suggested by meter manufacturer.

- Mount meter base in desired position.

- Meter base should be grounded. Use number 12 AWG copper wire for grounding purposes. Complete grounding process before external connections are made to meter.

- Make external connections to meter as shown in manufacturer’s instructions. The connections should be made by working from right to left. This ensures complete connection of meter to its LOAD circuit before LINE voltage is applied. Disconnection of meter should be made in reverse order.

- For connections of pulse initiators, refer to manufacturer’s instructions for particular type of end device being operated by the pulse initiator.

COMMON ELECTRICITY METERING PROBLEMS: Problems often encountered in the field while metering electricity fall into four categories: wrong meter, meter incorrectly wired, multipliers not calculated correctly, or the meter is not calibrated.

1. Wrong Meter: This problem occurs when the meter is incorrectly specified for the circuit. A common example of this is when a two stator meter is specified for a four wire wye circuit. The meter is often wired as if the circuit is a delta circuit. However, if the phases are even minimally unbalanced, the current flowing through the neutral wire will not be metered and the readings inaccurate. SOLUTION: Consult the manufacturers literature and specify the proper meter for the circuit.

2. Incorrect Wiring: It is estimated that between 5 to 10% of the electricity meters on navy bases are incorrectly wired. There are several ways the wiring can be wrong.

2.1 Current leads, potential leads , or instrument transformers could be reversed or out of rotation or phase. The phase angle between the current and the voltage for each phase to be wrong, resulting in erroneous readings by the meter. SOLUTION: Ensure meter IS wired correctly. Determine the nature of the load being metered and estimate its power factor. Then use a power factor meter on the incoming potential and current wires to determine if the meter is reading the estimated power factor.

2.2 Blown Potential Fuses: If fuses protecting potential transformers (PTs) are blown, the meter could be missing one or more phases of the load and running at 1/3 or 2/3 of normal speed. SOLUTION: Ensure that fuses for PTs are not blown. On most panel mounted meters, each PT circuit has a small light that, when lit, indicates that the circuit is operating properly.

3. Incorrect Multipliers: The multipliers have been incorrectly calculated, resulting in the register readings being multiplied by the wrong numbers. This often occurs when meters have been switched to a new location with different sized CTs or PTs, or when a meter has been repaired and the register changed. SOLUTION: Ensure that the values for the CT and PT ratios, Kh, Rr, and Gr are correct. Recalculate Kr, the register multiplier, to ensure it is correct.

4. Uncalibrated Meter: Meters built by major manufacturers are designed to run several years before calibration. However, depending on their use, navy meters should be calibrated from once per year to once every 5 years. SOLUTION: Field calibration of permanent meters can be performed by installing a portable meter In series with the permanent meter, timing the revolutions of the rotor, and comparing the kW demand of the permanent meter to that of the portable meter. This method should be accurate to within 5-10% . More accurate calibration requires the removal of the meter from the circuit to use a calibration stand.

ELECTRICAL METERING COMPONENTS

previous METERS AND SUPPORT DEVICES

where:

kW = kilowatt Demand

n = number of pulses occurring over the counting interval

KWC = constant number of kilowatts per pulse (demand multiplier)

T = counting interval in hours

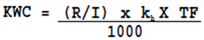

KWC, the watthour constant of the pulse devices, is calculated by:

where:

R/I = number of revolutions of the rotor per pulse. This is a constant provided by the manufacturer of the pulse device.

TF = transformer factor = CT ratio x PT ratio

kh = watthour constant

Two types of pulse devices are in common use, contact and pulse initiator.

For single-phase transformers or loads, multiply the above three-phase values by 1.73.

Example 1: A 5 kVA single-phase transformer has a secondary line current of 12 x 1.73 = 20.8 amperes at 240 V when operating at full load.

OTHER ELECTRICAL METERING COMPONENTS

1. Pulse Device (Digital): A widely used method of demand metering is the block interval, so called because a kWh measurement is totalized over a block of time, typically a 15- or 30-minute period. The most flexible and easily computerized block interval metering technique is pulse totalization. Each pulse represents a specified amount of kilowatt hours read by the meter from total or partial rotation of the disk. A pulse device can be retrofitted to most existing electromechanical watthour meters. These devices cause relay contacts to close at a rate proportional to load on the meter. Defined kilowatt demand is derived from relay closure pulses using the expression:

where:

kW = kilowatt Demand

n = number of pulses occurring over the counting interval

KWC = constant number of kilowatts per pulse (demand multiplier)

T = counting interval in hours

KWC, the watthour constant of the pulse devices, is calculated by:

where:

R/I = number of revolutions of the rotor per pulse. This is a constant provided by the manufacturer of the pulse device.

TF = transformer factor = CT ratio x PT ratio

kh = watthour constant

Two types of pulse devices are in common use, contact and pulse initiator.

1.1 Contact Devices: A contact device is entirely mechanical, consisting of a multilobed cam, connected into the watthour geartrain. The cam actuates one or more contact sets. All components of the device are mounted on a single backing plate that bolts into the meter mechanism under a glass dome. Three contact configurations are available (Figure 9-12). The different contact devices available service different electromechanical kW demand totalizer configurations. Slow-break contacts, for example, are used for solenoid-operated totalizers and quick-break contacts for motor-operated units. The type of break mechanism is important when contact closures from a pulse initiator are interfaced to a microcomputer through a single digital interface channel. If the sudden drop caused by the cam produces contact bounce, corrective measures must be taken to ensure accuracy of microcomputer displays. High-speed logic circuits are sensitive to contact bounce and are able to resolve a train of pulses from a single bouncing contact switch closure. This problem can be eliminated using software designed to discard any data during a specified period of time following a switch contact.

1.1.1 Contact Device Drives: Most contact initiators are driven by a separate worm gear on the meter shaft. Some meters have up to 360 possible gear ratios using worm gear and sector combinations. Tables for determining equivalent cam teeth (EqT) can be used, given the number of points on a cam and the gear ratio from the meter rotor to the cam. These tables are available from the manufacturer. The disadvantages of contact devices have limited their installation in newer, more sensitive watthour meters. Newer meters produce lower torque per kilowatt and thus are more affected by frictional forces imposed by the cam operated switch. The increased requirement for higher pulse rates and lower spring tension on the contact have proven to increase maintenance problems. Nonmercury-wetted switch contacts experience bounce.

FIGURE 9-12. Contact Device Configurations

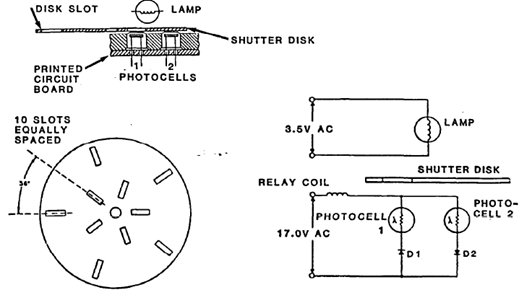

1.2 Pulse Initiators: The disadvantages of contact devices are absent in pulse initiator designs. A pulse initiator consists of a revolving shutter disk operated by a standard watthour meter geartrain. The disk, acting as a shutter, interrupts a beam of light to activate a photocell. Figure 9-13 shows the basic configuration of a shutter and the placement of the photocell and light source. The device is essentially frictionless and gives the same switch output as a contact initiator through a mercury-wetted relay. The bounceless contact closure data from pulse initiators are designed to interface with older pulse-totalizing equipment. Pulse initiator modules can be retrofitted to most watthour meters. A typical pulse initiator has one shutter disk with ten slots, producing one pulse per slot. Shutters are available with two, four, six, or eight slots.

FIGURE 9-13. Photocell Initiator

2. Instrument Transformers: To have meters function effectively within their capabilities, current transformers and potential transformers are used. Intended for measurement and control purposes, they perform two primary functions:

- Transform line current or voltage to values suitable for standard instruments which normally operate on 5 amperes and 120 volts.

- Isolate instruments and meters from line voltage. To make this protection complete for both instruments and operators, THE SECONDARY CIRCUIT SHOULD BE GROUNDED. For grounding , see IEEE Standard 52, Application Guide for Grounding of Instrument Transformer Secondary Circuits and Cases.

2.1 Current Transformer: Current transformers (CT) are designed to have the primary winding connected in series with a circuit carrying current to be measured or controlled. The secondary winding will then deliver a current proportional to the line current for operation of meters, instruments, and relays. In cases of portable instrumentation, ammeter and current coils of the wattmeter usually obtain their current signal from a clamp-around current transformer. This CT is used to step down line current to a level that can be conveniently metered, generally to 5 A or less. The CT surrounds the primary conductor and produces a secondary current proportional to the magnetic field created by the primary current in the conductor being measured. The ratio of primary current to secondary current is known as the CT ratio or CTR. CTs are normally rated in values to 5 A such as 100:5, 1000:5, and 5000:5. These values indicate how many amperes flowing in the primary conductor will cause 5 A to flow in the secondary winding. Current transformers must be selected for each application as shown in Table 9-1. In each instance, the secondary winding ratio should result in a secondary output of 5 amps at full-rated primary current. As an example, a 1,000-amp current transformer has a ratio of 200 to 1 and a 50-amp transformer has a ratio of 10 to 1. The secondary of a CT shall always be a complete circuit whenever there is current flowing through the primary conductor. Thus, leads of a CT shall never be fused and shall always be either connected to a low-resistance ammeter movement or shorted together by means of a jumper wire, screw, or switch on a CT shorting terminal strip.

Figure 9-14 is an example of how an ammeter, voltmeter, wattmeter, and a watthour meter may be connected through instrument transformers to a high-voltage line. It is extremely important that manufacturer’s manuals be followed to ensure a proper meter hookup.

FIGURE 9-14. Connection of Instrument Transformers

2.1.1 Mechanical Construction: Current transformers are classified as follows:- Window type: This type has a secondary winding completely insulated and permanently assembled on the core, but has no primary winding. This type of construction is commonly used on 600 volt class current transformers.

- l Bar type: Same as the window type except a primary bar is inserted into the window opening. This bar can be permanently fixed into its position or be removable.

- Wound (wound-primary) type: “This type has primary and secondary windings completely insulated and permanently assembled on the core. The primary is usually a multiturn winding.

2.1.2 Electrical Connection: The following are types of CTs based on electrical connection:

- Single primary: This term is frequently applied to current transformers having a single primary electrical circuit and is generally used to distinguish them from current transformers having series-parallel primary windings.

- Window type with one or more primary turns: A single conductor straight through a window type transformer is a “one turn primary” connection.

If this single conductor is taken through the “window” twice, the nameplate primary rating is reduced by 1/2. (Multiply meter reading by 1/2 the CT nameplate ratio).

If on a single-phase, three wire circuit, two different leads are taken through the same window transformers, the nameplate primary rating is reduced by 1/2 (multiply meter reading by 1/2 the CT nameplate ratio). - Double ratio: Double ratio units are built either with a two-part series parallel winding or with a tap on a secondary winding.

2.2 Potential Transformer: Potential transformers (PT) are designed to have the primary winding connected in parallel with a circuit, the voltage of which is to be measured or controlled. The secondary winding will then deliver a voltage proportional to line voltage for operation of meters, instruments, and relays. A PT is used to reduce line voltage to a level to match the meter rating, generally 120 V. The ratio of primary to secondary voltage is known as the PT ratio or PTR. The leads on a PT shall always be fused and shall never be shorted together. Voltage transformers are available in many accuracy classes; it is important to select one suitable for a specific application. Figure 9-14 shows how a voltmeter would be connected to a potential transformer in a high-voltage circuit. In this instance the turns ratio would be 120 to 1. As with CT hookups, the manufacturer’s manual should be consulted and followed to ensure the meter is properly connected in the circuit.

TABLE 9-1. FULL-LOAD LINE AMPERES FOR THREE-PHASE* TRANSFORMERS OR LOADS

For single-phase transformers or loads, multiply the above three-phase values by 1.73.

Example 1: A 5 kVA single-phase transformer has a secondary line current of 12 x 1.73 = 20.8 amperes at 240 V when operating at full load.

Example 2: Assume the load to be metered is fed by a 500 kVa transformer at 208 volts on the secondary. If the load is metered on the secondary side of the transformer, the ammeter will see a max current of 1,388 amps. Thus a current transformer with a ratio of 400 to 1 (2,000/5) should be used.

2.2.1 Secondary Circuit: Potential transformers are classified by the type of design of the secondary circuit.- Single secondary: In general, standard rating potential transformers, 15 KV class and below, are supplied with a single electrical secondary circuit designed for 120 volts.

- Tapped secondary: There are applications where it is desirable to have two or more values of secondary potential available from the same secondary winding. This is particularly true where it is desirable to connect the secondary winding in delta or wye, for three-phase circuits, and obtain the same secondary voltage.

For such applications, the’ transformer secondary is rated at 120 volts with a tap at 69.3 volts. - Double secondary: Unlike current transformers, double or multisecondary potential,transformers have individual secondary electrical circuits on the common magnetic core. These windings may or may not be tapped. Each secondary is affected by the burden conditions on the other secondaries.

2.3 Transformer Accuracy: Because of the function they perform, all instrument transformers must be classified as to accuracy. The two most important specifications for these transformers are ratio accuracy and phase-angle error. Phase-angle errors should be less than 50 minutes for use with analyzers of the 99 percent accuracy class and 10 min. or less when used with instruments having accuracies of 99.75 percent or better. It is noted that control transformers are not suitable for metering since their voltage can be off by 10 percent.

2.4 Instrument Transformer Polarity: When instrument transformers are used with instruments or relays which operate only according to the magnitude of the current or voltage, the phase position or direction of flow of current is of no consequence; connection to the secondary terminals may be reversed without changing indication of the instrument. When instrument transformers are used with watthour meters, in which the operation depends on the interaction of both current and voltage, the direction of current in the primary and secondary windings must be known. This is indicated by marking one primary and one secondary terminal with a distinctive POLARITY MARKER. When current is flowing toward the transformer in the marked primary lead, it is flowing away from the transformer in the marked secondary lead.

2.5 Grounding: It is always desirable to ground a transformer rated meter and also to ground secondaries of both the current transformer and the potential transformer. This avoids danger of high electrostatic voltages that might otherwise be present as a result of the capacitance (condenser effect) of the potential-transformer windings. This grounding practice also minimizes hazard from high voltages reaching the secondary circuit as a result of insulation breakdown due to lightning surges or other abnormal circuit conditions.

METERS AND SUPPORT DEVICES

previous CONCEPTS OF METERING ELECTRICITY

where:

Rr = register ratio found on front plate, back plate, or frame of register

Kh = watthour constant

TF = transformer factor = CT ratio x PT ratio

Gr = first gear reduction ratio usually 50 or 100 (obtain from manufacturer)

Self-contained meters, used for domestic service and small industry, usually have a multiplier of either 1, in which case no multiplier would be shown, or 10. Whenever the multiplier is more than 1, the words “multiply by”, followed by a number appear on the front plate. For transformer-rated meters, which are used with instrument transformers for heavy industrial and central station metering, the multiplier can be 10, 100, 1,000, 10,000, etc. In this case the register is supplied for only one transformer factor. The multiplier can also be numerically equal to the transformer factor. If so the register will read in terms of secondary energy and be read on a “secondary-reading register*’. In any watthour meter, the total energy in kWh is equal to the product of the watthour constant (Kh) and the disk revolutions divided by 1,000:

Accurate and reliable data can be obtained using either permanent or portable meters. Permanent meters are generally installed at service entrances and at points of large power demand. To perform a power demand survey, it may be necessary to monitor many additional locations within a system. It may not be economical to install permanent meters at each location, so portable units are used. The cost of portable meters is higher than permanent meters but their accuracy is generally very good.

METERING DEVICES

1. Watthour Meter: Consumption of electrical energy is measured with either a mechanical or electronic watthour meter.

1.1 Mechanical Watthour Meter: A mechanical watthour meter is a small, precision built, induction motor. It consists of a rotating disk, electromagnet, permanent damping magnet, bearings, geartrain, and dial assembly. The electromagnet is wound with a voltage coil and a current coil. When the meter is energized, a small current flows through the voltage coil, connected across the lines, and full load current flows through the current coil. The current in these coils sets up magnetic fields, or magnetic flux that induce small currents (called eddy currents) in the disk. These eddy currents set up their own magnetic field. The combination of fluxes, or magnetic fields, interact with one another in such a manner that the disk is forced to rotate in a positive direction. With voltage and current coils energized, the disk gathers momentum and spins faster. Therefore, a braking device to retard disk speed is provided. The braking device is a permanent magnet through which the disk rotates.

1.2 Electronic Watthour Meter: An electronic watthour meter consists of a current sensor, kilowatt transducers electronic totalizer, and mechanical or electronic digital display. Sensor, transducer, totalizer, and display combinations are available for readings of watthours to megawatthours. As with most electronic power monitoring equipment, the cost is high. Most electronic kWh meters are used in conjunction with computerized energy management systems.

1.3 Watthour Meter Selection Criteria: Some facts that should be known or considered before purchasing and installing a meter are as follows:

- Type of service: single-phase network, 3-wire; 3-phase, 3- or 4-wire; wye (Y) or delta (Δ)

- Circuit voltage: line-to-line or line-to-neutral, depending on meter connections. Determine if requirement exists for PT with current limiting primary fuse.

- Maximum circuit current: assume for current estimating purposes that 1 horsepower = 1 kW = 1 kVA. Determine CT ratio if load is above meter class rating.

- Mounting: socket (S) or bottom-connected (A).

- Register: 4-dial or 5-dial pointer; 4-dial or 5-dial cyclometer; cumulative demand register with 15-minute interval.

- Frequency: check value.

- Compliance to standards: ANSI C12.10, Watthour Meters.

- Special features: pulse device.

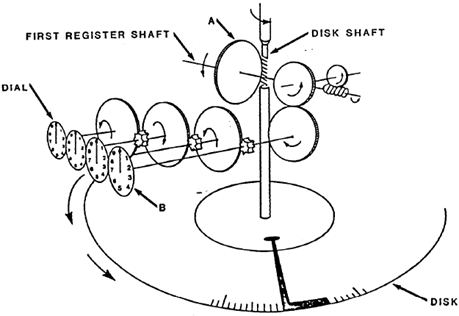

1.4 Watthour Meter Register: A register of a watthour meter is a geartrain designed to count the number of revolutions of the disk (Figure 9-5). Rather than displaying the number of disk revolutions directly, the register derives kilowatthours by the number of disk revolutions. Registers are either pointer type or cyclometer type (Figure 9-6).

1.5 Meter Terminology: To facilitate an understanding of operation, testing, and accuracy of meters, it is helpful to recognize the meaning of certain abbreviations in common use:

Kh = The number of watthours represented by each revolution of the meter disk.

Kr = The register constant. This is the value that a register reading must be multiplied by to obtain the correct kWh registration.

Rr = Refer to Figure 9-5. A ratio of the number of revolutions of first register shaft (A) to each complete revolution of the first pointer shaft (B). The gear marked A is driven by the disk shaft.

Gr = Gear reduction ratio between the disk shaft and the gear (A in Figure 9-5) which meshes with it.

TF = Transformer factor which is the product of the current transformer ratio (CTR) and the potential transformer ratio (PTR).

PKh = Primary meter constant = Kh x TF

1.6 Meter Nameplate: The meter nameplate provides important information in addition to totalized watthours (Figure 9-7).

1.6.1 Class: Modern meters will measure accurately up to 800 percent of full load calibration test amperes. This is denoted by “CL”, or class, on the nameplate. Use Class 20 meters with instrument transformers to obtain straight line accuracy up to 20 amps and also use with CTs with 5 amp secondaries. Class 10 and 20 meters are for use with instrument transformers only . Class 100, 200, and 320 meters are designed to directly meter the line current.

Class 10: 2.5-amp meter with 400 percent overload capability

Class 20: 2.5-amp meter with 800 percent overload capability

Class 100: 15-amp meter with 400 percent overload capability

Class 200: 30-amp meter with 666-2/3 percent overload capability

Class 320: 50-amp meter with 640 percent overload capability

Class 20: 2.5-amp meter with 800 percent overload capability

Class 100: 15-amp meter with 400 percent overload capability

Class 200: 30-amp meter with 666-2/3 percent overload capability

Class 320: 50-amp meter with 640 percent overload capability

There are some exceptions to the rule. Refer to manufacturers instructions to be sure of the correct application for a particular meter.

FIGURE 9-5. Watthour Meter Geartrain

FIGURE 9-6. Meter Registers

FIGURE 9-7. Meter Nameplate

1.6.2 Register Multiplier (Kr): To obtain the correct number of kilowatthours, it may be necessary to multiply the value shown on the meter by a register multiplier or register constant Kr. The value of Kr, although shown on the meter nameplate, can be calculated as follows:

where:

Rr = register ratio found on front plate, back plate, or frame of register

Kh = watthour constant

TF = transformer factor = CT ratio x PT ratio

Gr = first gear reduction ratio usually 50 or 100 (obtain from manufacturer)

To determine total energy in kilowatt hours as counted by a transformer-rated meter, the secondary reading register would be multiplied by the ratio of the instrument transformers which is called the transformer factor. In a system using current transformers with a rated primary current of 20 amperes, total energy registered would equal:

If the system also contained a PT with a 7,200 to 120 ratio, the total energy registered would equal:

In this example, the numbers 4 (20/5) and 60 (7,200/120) are the ratios of CT and PT respectively. Their product, 240 (4 x 60), is the transformer factor for this meter. Whatever value is shown on the secondary register must be multiplied by the transformer ratio to obtain the correct number of kWh used in the primary circuit.

1.6.3 Voltage Rating: Meters are available for 120-, 240, or 480-volt service as required.

2. Permanent Kilowatthour Meter: A typical kilowatthour meter is shown in Figure 9-8. Watthour meters are commonly known by the type of electrical system for which they are designed , such as 3-wire single phase and 4-wire delta or wye meters. Basic characteristics of a typical kilowatthour meter are as follows:

- Configuration: Kilowatthour meters are available to measure energy consumption for all types of single and polyphase circuits. Two types of mountings are available: hard-wired A-type meter and socket and plug-in, S-type meter. In addition to standard registers, threevoptions are available: time-of-use register, demand register, andvpulse initiator.

- Register: Totalized kilowatthours (kWh) are displayed either in a four or five circular dial arrangement, or in digital form.

- Range: Self-contained meters are designed for services of up to 200 amperes and 600 volts. For higher voltages and currents, potential and current transformers are required. In many situations, for safety considerations, a potential transformer (PT) is preferred when voltages exceed 277 volts.

- Accuracy: Utility companies usually specify an accuracy of±2 percent and conformance to American National Standards Institute (ANSI) c-12 series standards.

- Installation: Power service must be interrupted to install an S- or A-type kilowatthour meter. If service cannot be interrupted, clamp-on split core transformers may be used. Core transformers are generally used as a temporary measure or for spot monitoring.

FIGURE 9-8. Kilowatthour Meter

2.1 S- and A-Type Kilowatthour Meters: The S- or A-type designation on a kilowatthour meter refers to the counting configuration. An S-type meter is a socket-mounted meter. A socket is hard wired into position and the meter is then plugged into the socket. The meter can then be removed any time without disconnecting wiring. The A-type meter is hard wired into position at the time of installation and requires complete disconnection of wiring for removal.

2.2 Transformer-Rated Kilowatthour Meters: If connected load exceeds 200 amperes and/or voltage of a circuit exceeds 600 volts , a transformer-rated kWh meter must be used in conjunction with instrument transformers. For safety reasons, transformers should be used when voltage exceeds 277 volts, even though meters without transformers are supplied for 480 and 600 volt service. Transformers reduce the voltage and line current to meter operating range. Both current and potential transformers are used for this purpose. Transformers can be either an integral part of the meter or a separate component. In using transformer-rated meters, it is important to know that two values of Kh may be shown on the meter nameplate. The first Kh which is a small numeric value is the Kh of the meter itself. The second Kh which may be shown as Kt, in which the subscript “t” stands for test, is the value used when the meter is being tested. There is another term which should be understood; this is the primary Kh abbreviated Pri Kh or PKh which is followed by a numerically large number. This value is the number of watthours of primary energy for one revolution of the disk and is equal to the Kh (of meter) x Transformer Factor. The transformer factor is equal to the product of CT and PT ratios. The CT ratio is always the rating of the CT divided by 5 and the PT ratio is the voltage of the primary circuit divided by 120.

2.3 Three-Phase Circuits: Polyphase watthour meters are applied to both delta ( D ) and wye (Y) circuits.

2.3.1 Three-Phase, Four-Wire Y Circuits: A three-phase, four-wire circuit is equivalent to three single-phase, two wire circuits having a common return circuit with potentials 120 degrees apart. It can, therefore, be metered with three two-wire meters or with a three-stator polyphase meter as shown in Figure 9-9. Because the voltages of the three phases are balanced, it is common practice to use a 2-1/2 stator self-contained watthour meter to meter this circuit. Connections for a self-contained watthour meter are shown in Figure 9-10.

2.3.2 Three-Phase, Three-Wire Circuits: Metering of a three-phase, three-wire circuit is accomplished in accordance with Blondel’s theorem by means of a two-stator meter having current coils connected in two lines and corresponding potential coils connected from these lines to the third line. The connection of a transformer-rated meter is shown in Figure 9-11.

FIGURE 9-9. Three-Stator Polyphase Self-Contained Watthour Meter in a Three-Phase, Four-Wire Y Circuit

Figure 9-10. Two-and-one-half Stator Meter in a Three-Phase, Four-Wire Y Circuit

FIGURE 9-11. Two-Stator Watthour Meter Connected to a Three-Phase, Three-Wire Circuit With Current Transformers

2.4 Kilowatthour Meter Reading: If a meter has a dial type register, it will either have four or five dials, as shown in Figure 9-8. The correct reading for a five-dial meter is 34310; the correct reading for a four-dial meter would be 4310. Every other dial moves counterclockwise. When the pointer is between two numbers, record the lower of the two numbers. When the pointer appears to be directly on a number, look at the dial to the right. If the pointer on the dial to the right has passed "O” toward “l,” then use the number the pointer appears to be on. If the pointer on the dial to the right has not passed “O,” use the previous, lower number on the dial being read. Subtract the previous reading from the present reading to determine kilowatthours used during the time interval. If the words “multiply by*’ followed by a number appear on the meter nameplate, the reading on the register must be multiplied by the number shown to obtain the correct value.

2.5 Meter Recording Developments: Recent developments in the field of meter recording promise increased accuracy and automatic processing of data. Meters currently available allow meter readings to be recorded even when the meter is inaccessible. Another development allows meter readers to record meter data on a hand-held device which resembles a pocket calculator. The hand-held device is preprogrammed to automatically evaluate the entered reading for tolerance from past readings. If beyond a programmed tolerance, it alerts the meter reader to a possible recording error. Data must either be corrected or “force” entered, in which case this fact will be noted. The exact time the meter was read is recorded to the second. All types of meters can be serviced. At the end of the day, the device is placed into a computer interface. The interface equipment automatically feeds all the information obtained that day into computer data files. The system also prepares reports with format and information selected by the utility manager. Systems similar to this help eliminate human error.

2.6 Field Testing: The accuracy of a watthour meter can be checked using a simple time test. The number of watthours for any period is the product of the number of disc rotations times the meter constant (kh). The speed of rotation of the disc indicates the use rate or watts being used. The kilowatt is a more reasonable quantity for consumption rate and the following formula can be used when timing a meter disc:

PTR = potential transformer ratio

CTR = current transformer ratio

K h = meter constant found on the face of the meter

REV = number of disc revolutions during observation period

s = period of observation in seconds

pKb = primary meter constant Kh x (PTR x CTR)

A stopwatch can be used to check meter accuracy using the formula given above. The calculated kW can be compared against a known load. If load remains constant, results are quite accurate. However, since accuracy depends upon a constant load which may be impossible to obtain in the field, it may be preferable to compare the watthour meter being checked against a watthour meter standard of known performance. Since both meters will be connected in the circuit, small variations in voltage, current, or power factor will not introduce errors as both meters are observing the same loads.

3 Demand Meter: A demand meter is a kilowatthour meter with an accessory clock motor and counter mechanism. The basic type of demand meter indicates a single maximum demand during a given time interval, using a sweep pointer. Behind the front plate there is a pointer-pusher mechanism that advances the pointer. After each demand interval, the pointer-pusher is reset to zero by the clock while the pointer remains at its last indicated high point. Therefore, the maximum demand during a single interval is registered regardless of the number of intervals spanned. The q aximum demand, in addition to total kWh consumed, is used for billing purposes.

3.1 Demand Register: A demand register is the register on a demand meter that indicates maximum load demand during a given interval of time, usually a 15- to 30-minute period.

4.1 Portability: To enable different points in a system to be measured, the PSR must be portable rather than fixed. Physical size and weight of portable meters varies and may require consideration.

4.2 Full-Scale Ranges: Because of the range of load demands encountered during a survey, a PSR should be able to measure both very small and very large loads. PSRs typically have measurement limits of approximately 600 volts and 1,000 amperes. Potential transformers extend voltage range and current transformers increase current capability.

4.3 Split Core Transformers: Although it is preferable to install metering devices before a load has been energized , many loads may be considered too critical for shutdown. In such instances , split core transformers may enable measurements to be made. With such devices, the circuit need not be interrupted for insertion of current meter elements.

4.4 Accuracy: A PSR must be accurate across the entire range of scales and parameters available. Poor accuracy reduces validity of calculations that are based upon PSR data.

4.5 Temperature and Humidity Limits: A PSR must be capable of providing accurate, reliable information in all climatic conditions encountered.

4.6 PSR Voltage and Frequency Requirements: Selectable voltage inputs for a PSR is advantageous. Metering in various locations may give rise to differing voltage requirements. Should voltage requirements exceed 600 volts, PT will normally provide the needed additional capability. Although only one frequency may be encountered at any particular facility, the PSR selected should be able to measure power at whatever frequency is present.

4.7 Availability and Compatibility: PSRs of various capabilities are available in the commercial marketplace. Prices and accessories vary considerably. When renting, leasing, or purchasing equipment, ensure that all components needed to undertake a complete survey are obtained. Additionally, ensure that survey equipment components are compatible with each other.

5. Tape Recorder Meters: A tape recorder meter is used often for periodic monitoring because it provides a graph that is easy to analyze. Tapes offer immediate data for use in comparing actual power demand with rate schedule provisions of the utility. These meters are portable and do not interrupt service when connected. The meter uses clamp-on type current transformers and may use battery power or 100 volts alternating current (VAC).

6. Time-of-Use Meter: Time-of-use meters have not changed for many years; improvements to them have been evolutionary rather than revolutionary. With availability of integrated circuit processors and electronic digital memories, tasks performed by these meters that were originally difficult or impossible, are now easier. This meter is based on a standard watthour meter structure with pulse output to an integral microprocessor-based register. With a precise internal clock it can be programmed to handle any time-dependent provisions in a rate schedule, such as time-of-day and time-of-year rate changes. The reduction of meter data can provide the following types of information:

- Total kWh

- Onpeak kWh

- Mid-peak kWh

- Offpeak kWh

- Onpeak kW demand

- Mid-peak kW demand

- Offpeak kW demand

7.1 Power-Factor-Meter: A power-factor meter indicates either a single or three-phase value leading or lagging. It requires both potential and current connections much the same as a wattmeter. Most power-factor meters are single-phase devices and are not accurate on either imbalance voltage or current on a three-phase system. Some electronic meters respond to zero crossings and, in the presence of distortion, are not accurate.

7.2 Negative Sequence Meter: A negative sequence meter indicates the presence and magnitude of negative sequence voltage or current, usually associated with system imbalance, fault conditions, or both.

Subscribe to:

Posts (Atom)